- Home /

LED Strip Lights /

White LED Light Strips /

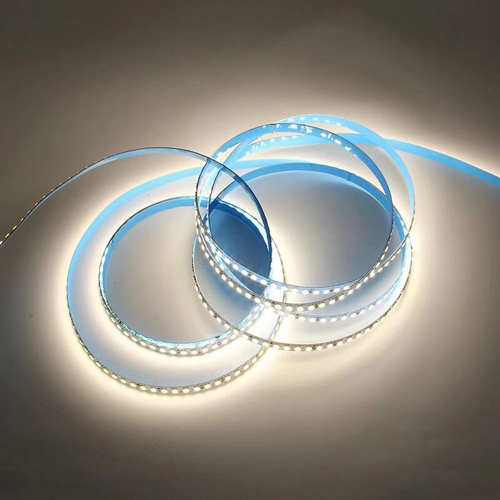

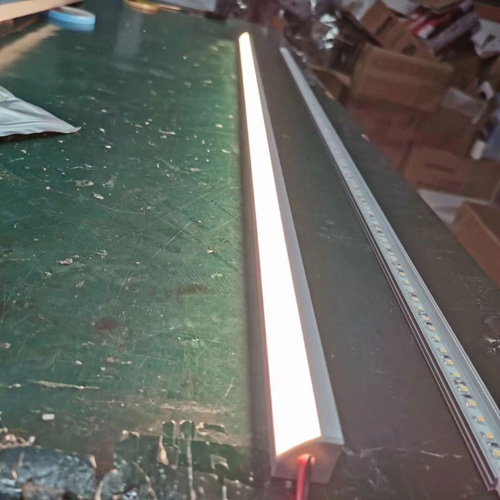

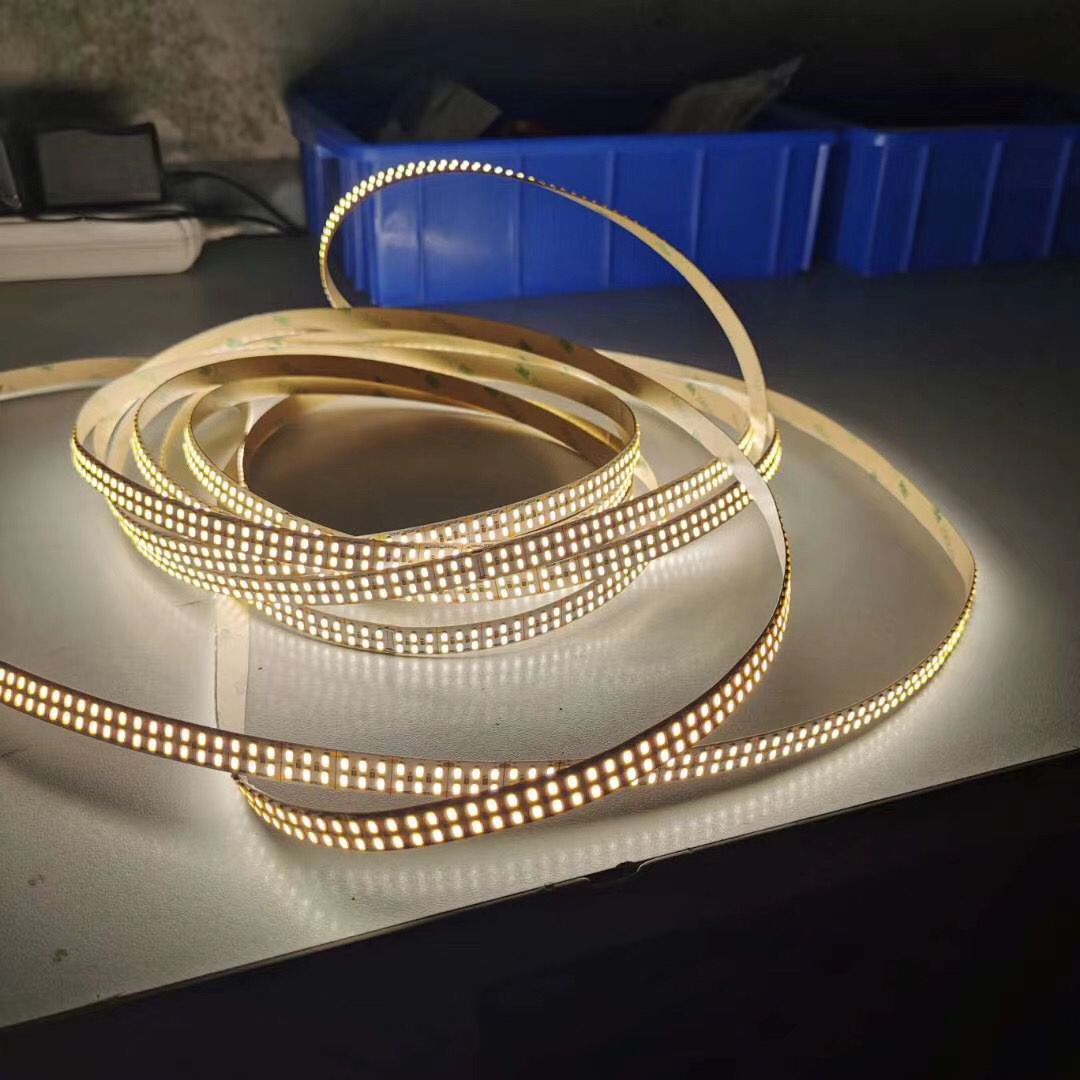

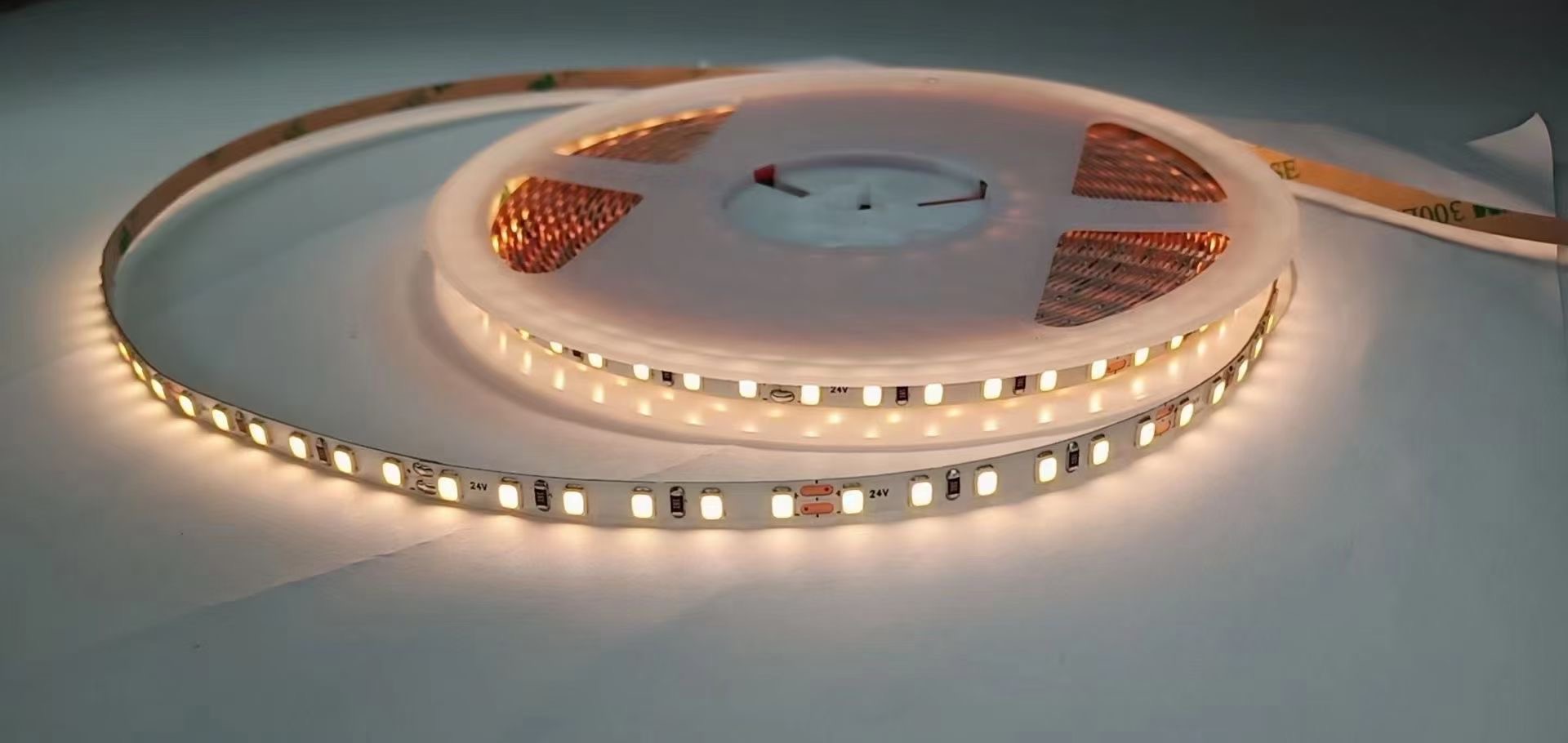

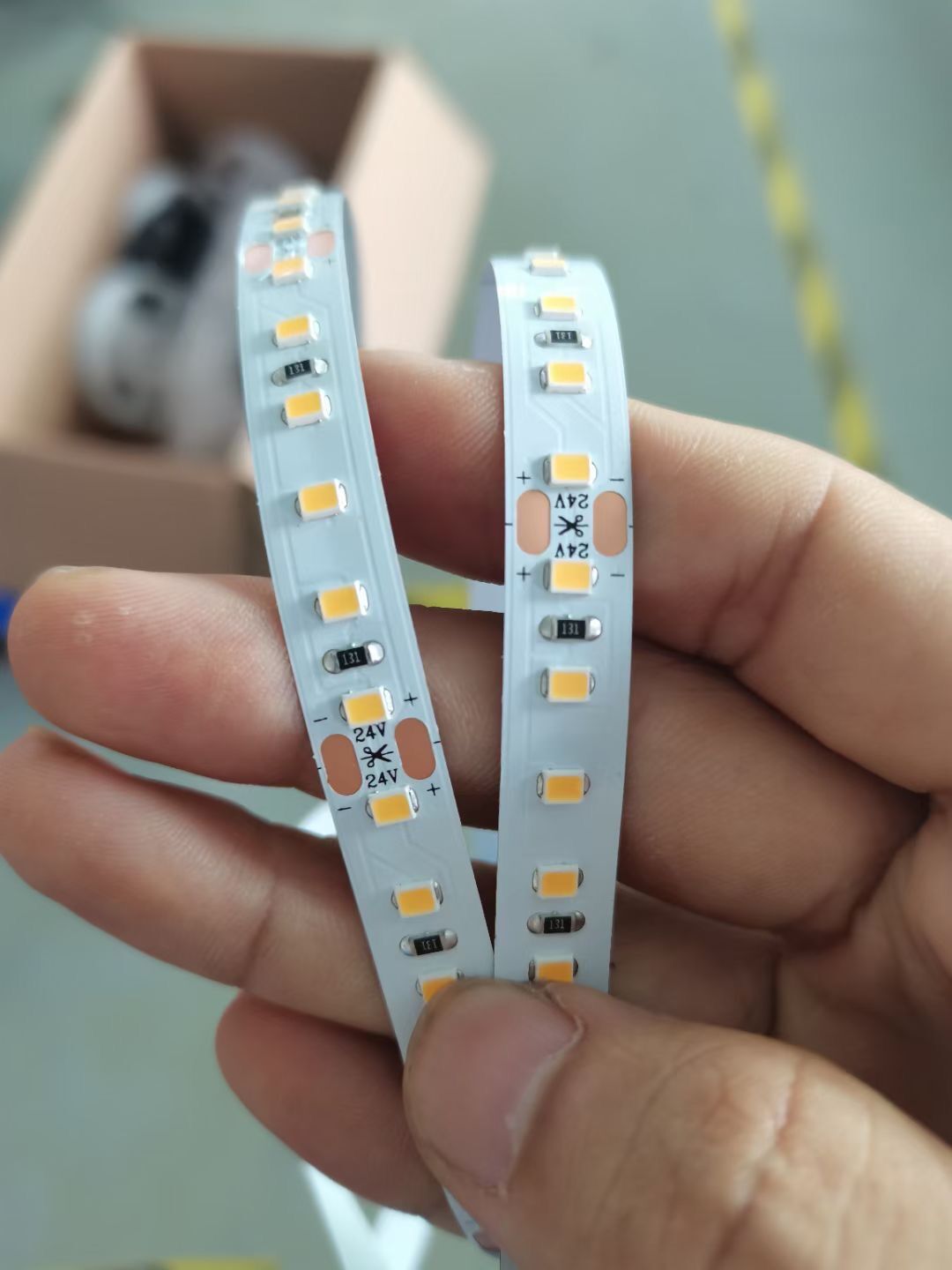

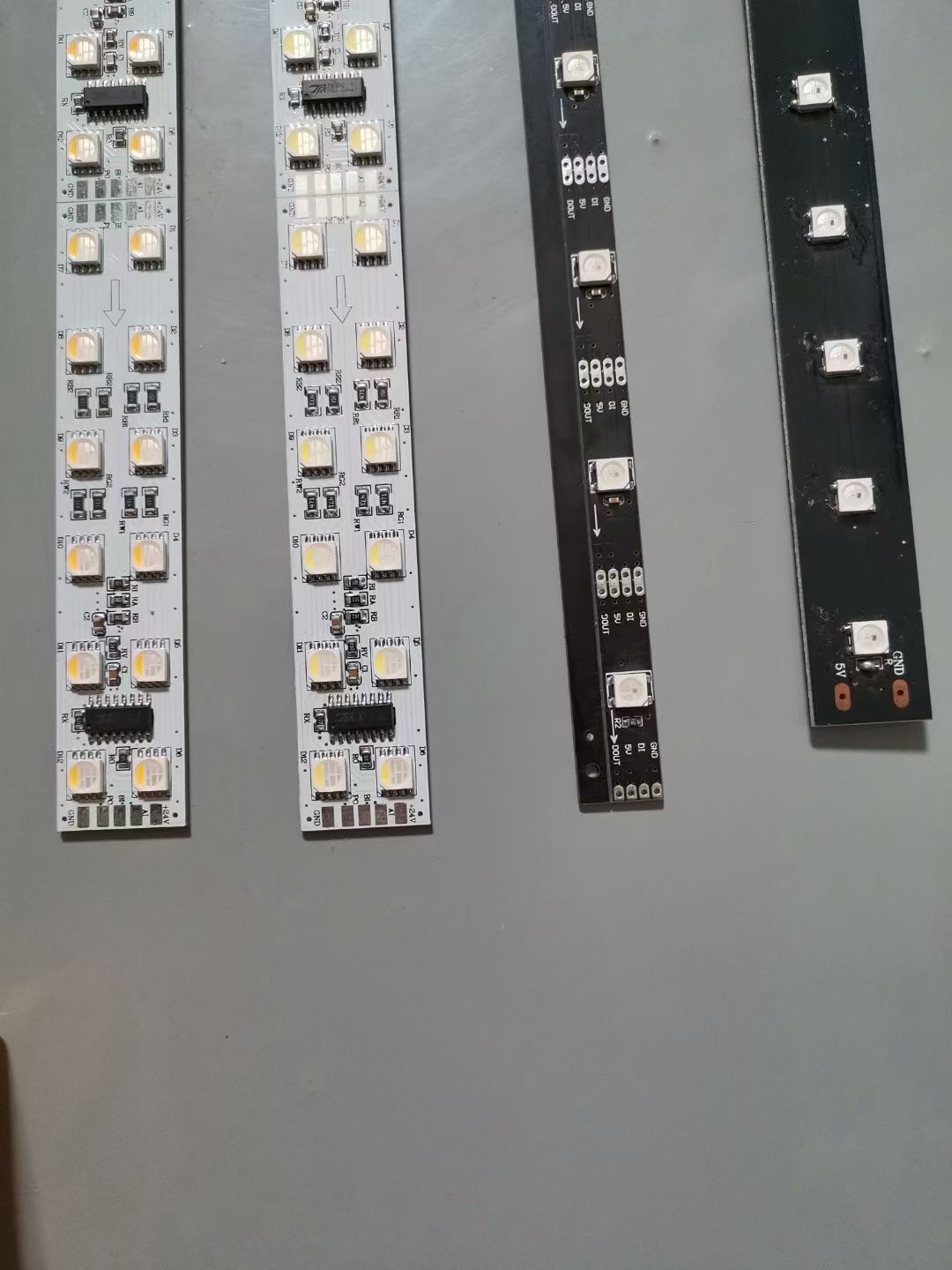

5m White LED Strip Light - Bright Triple Row LED Tape Light - High CRI - 24V - IP20 - 1,158 lm/ft

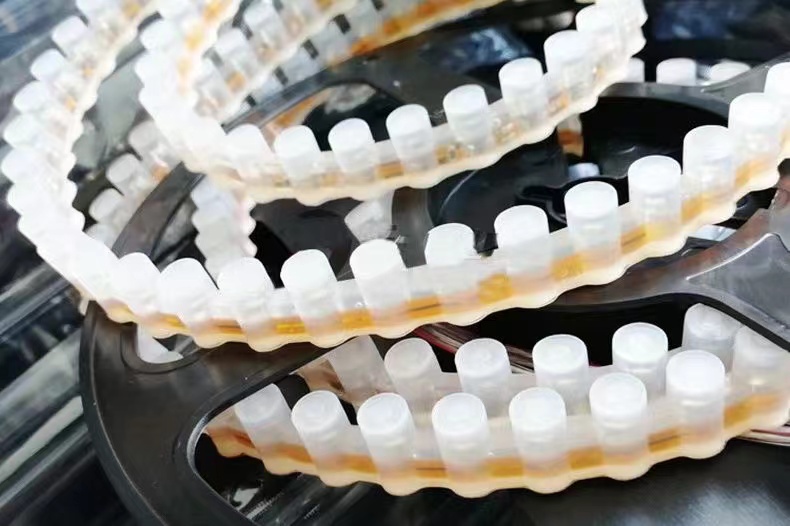

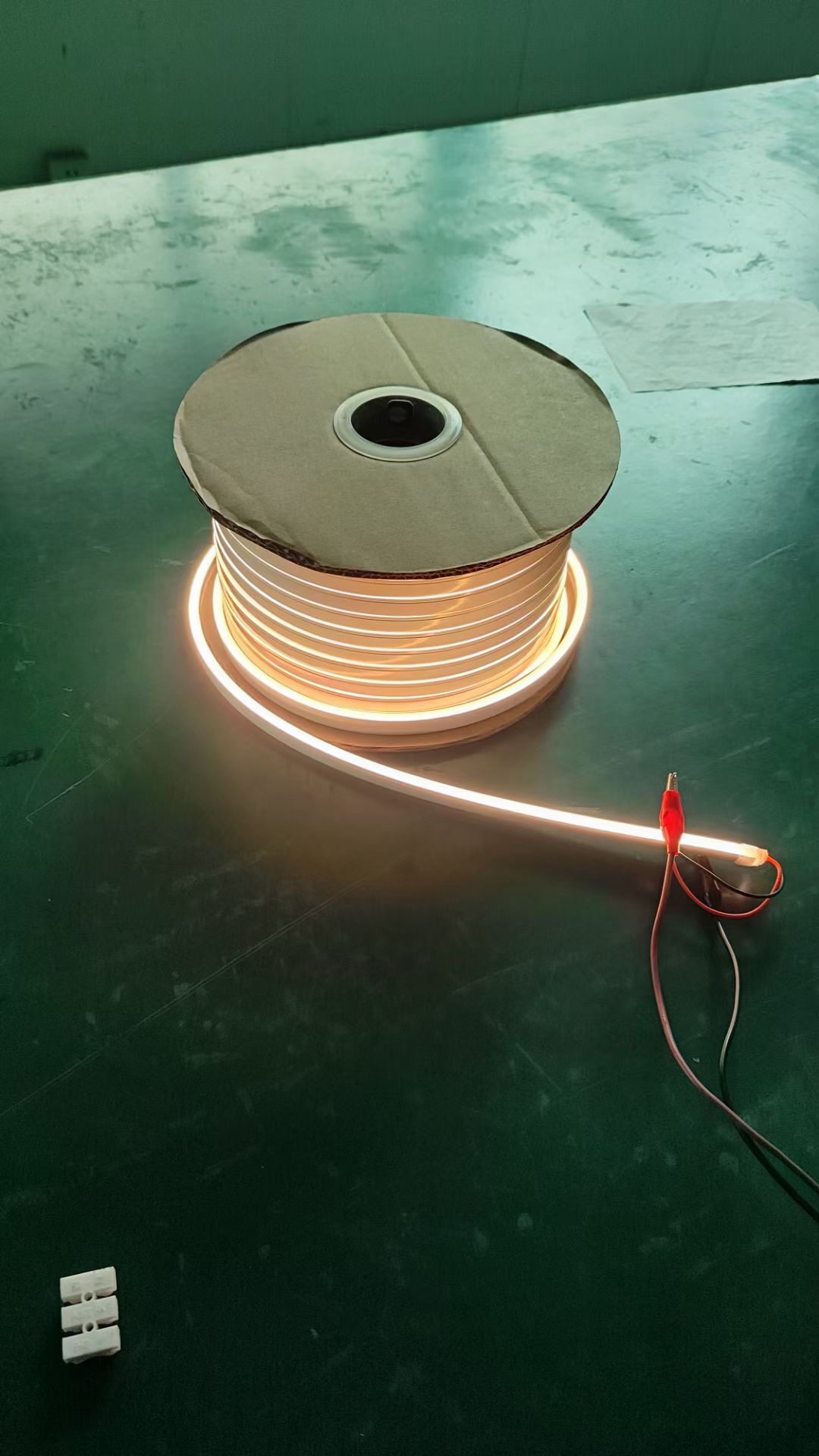

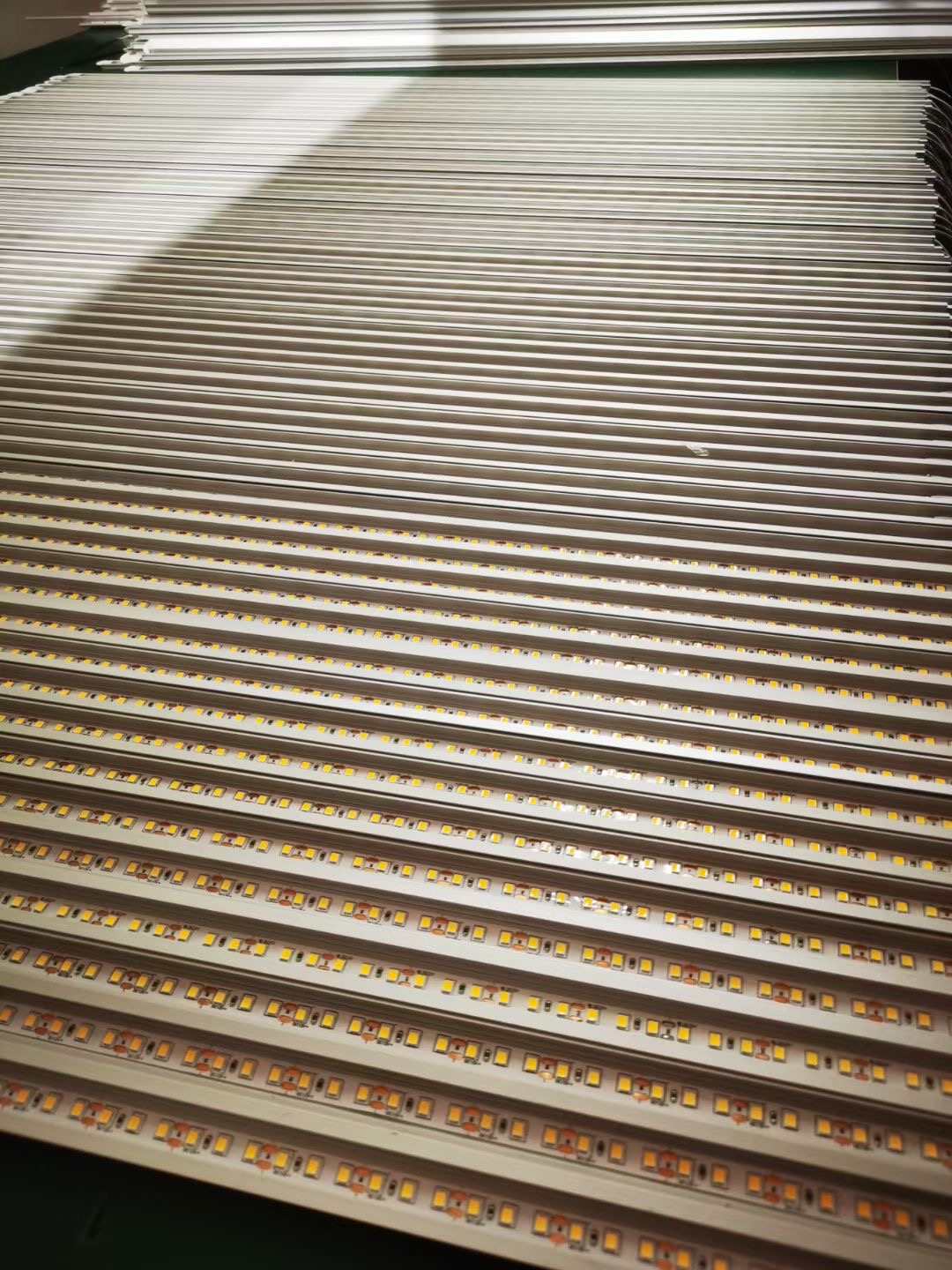

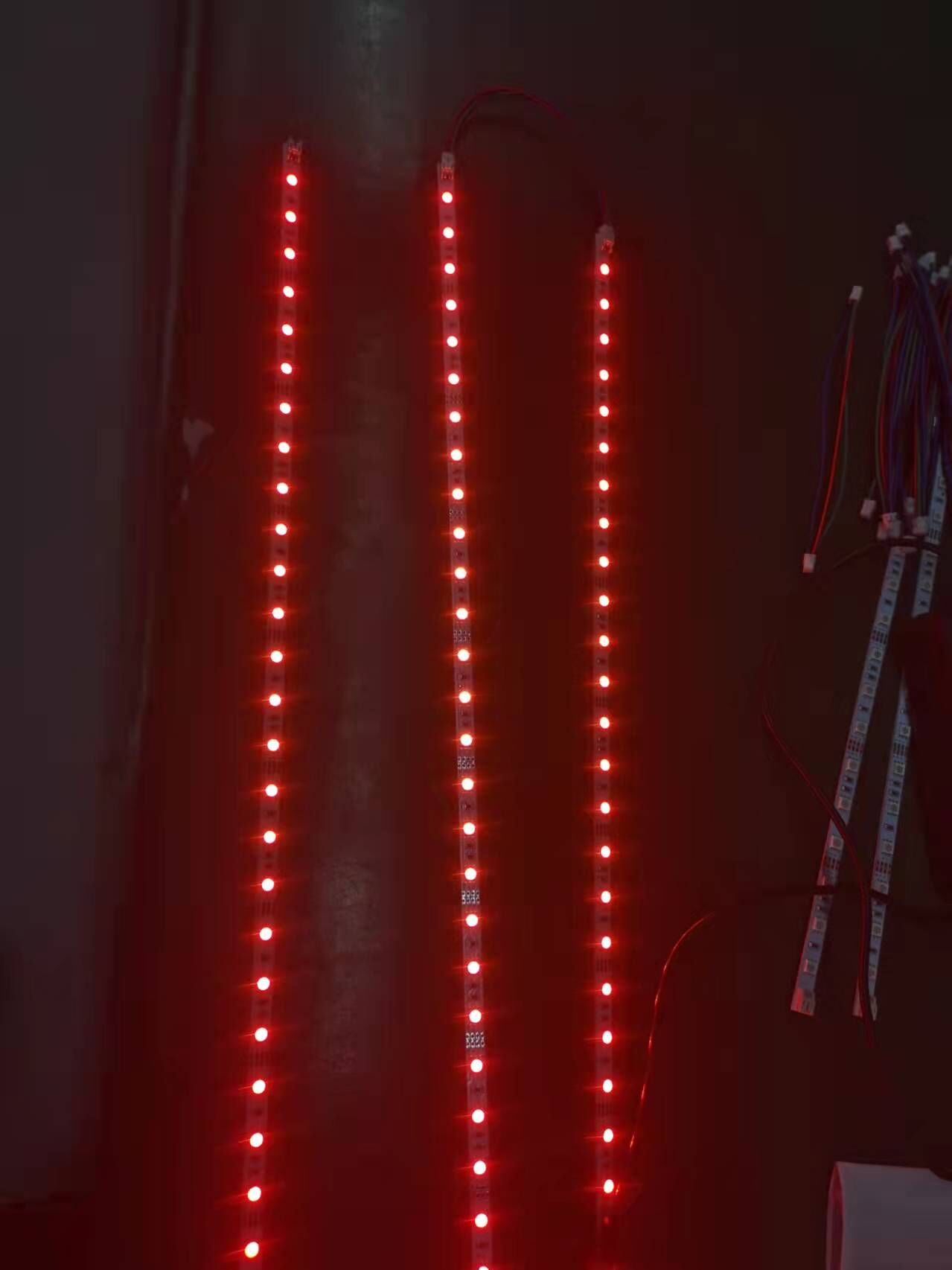

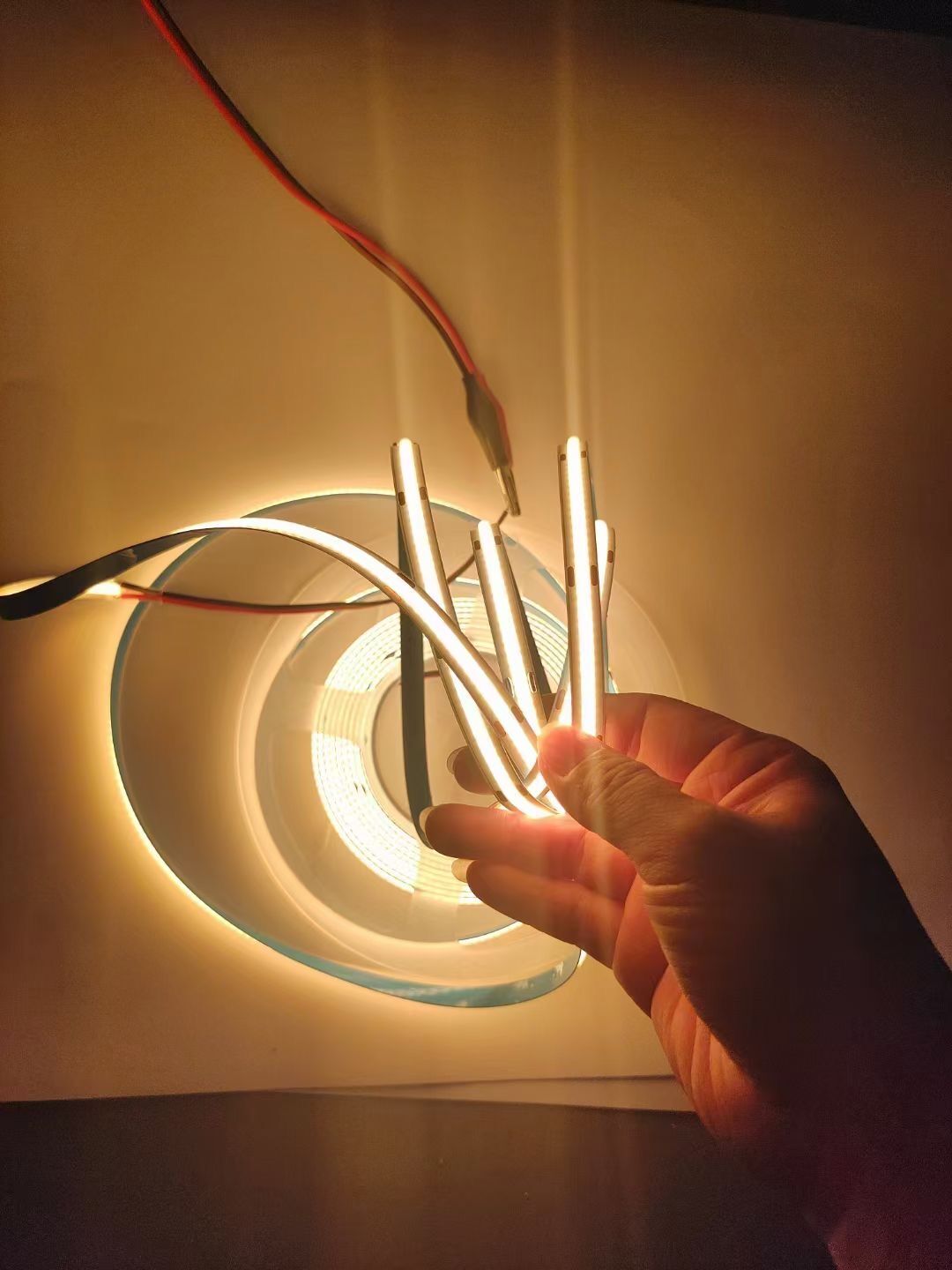

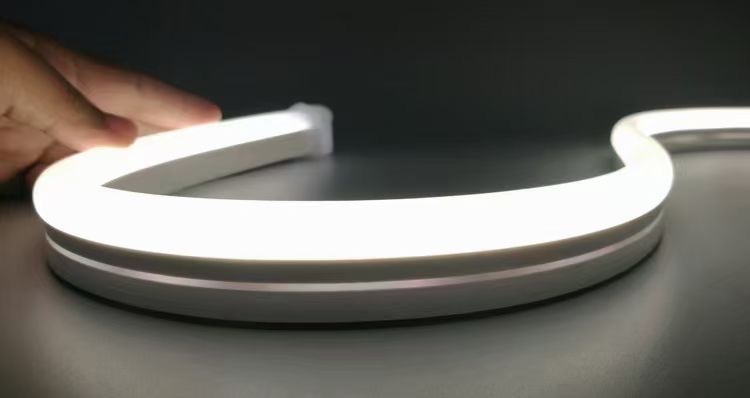

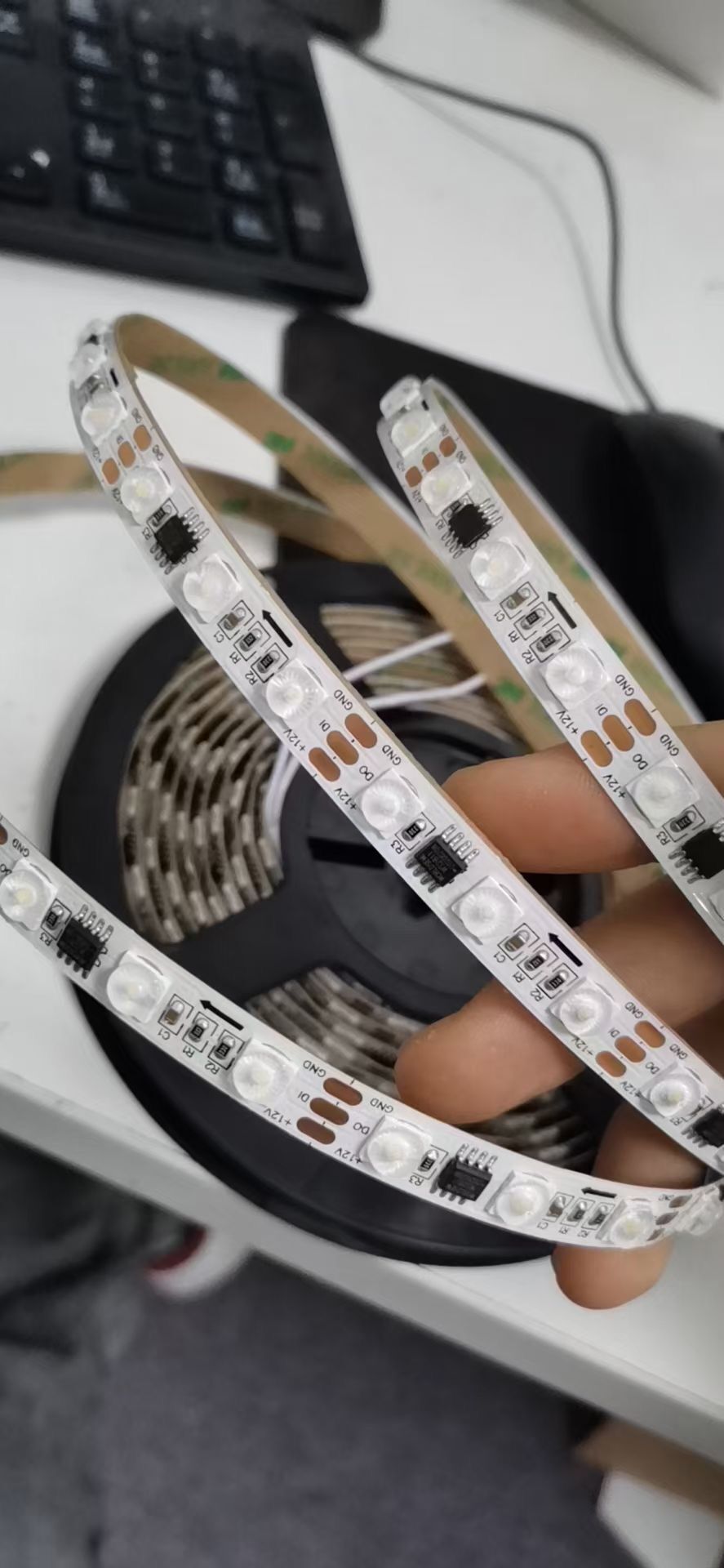

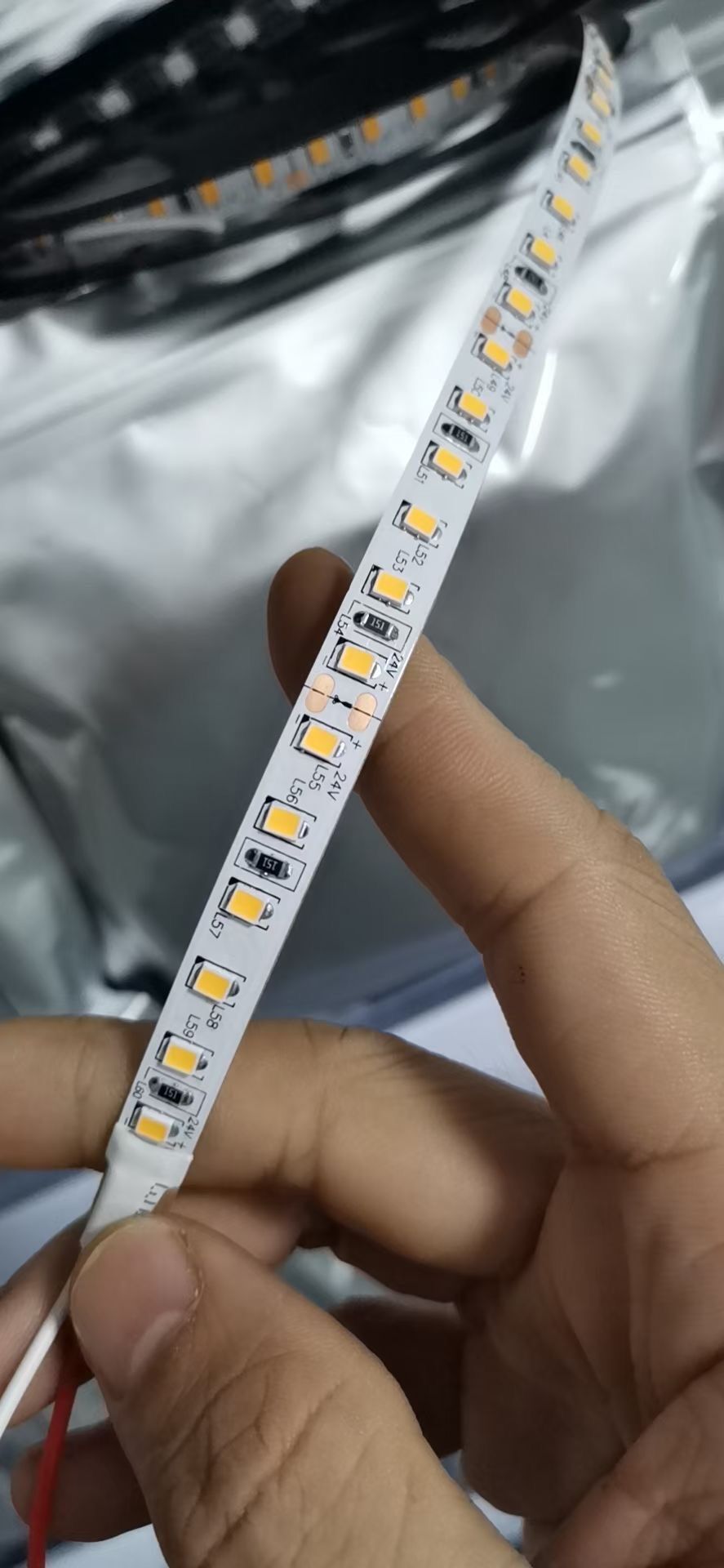

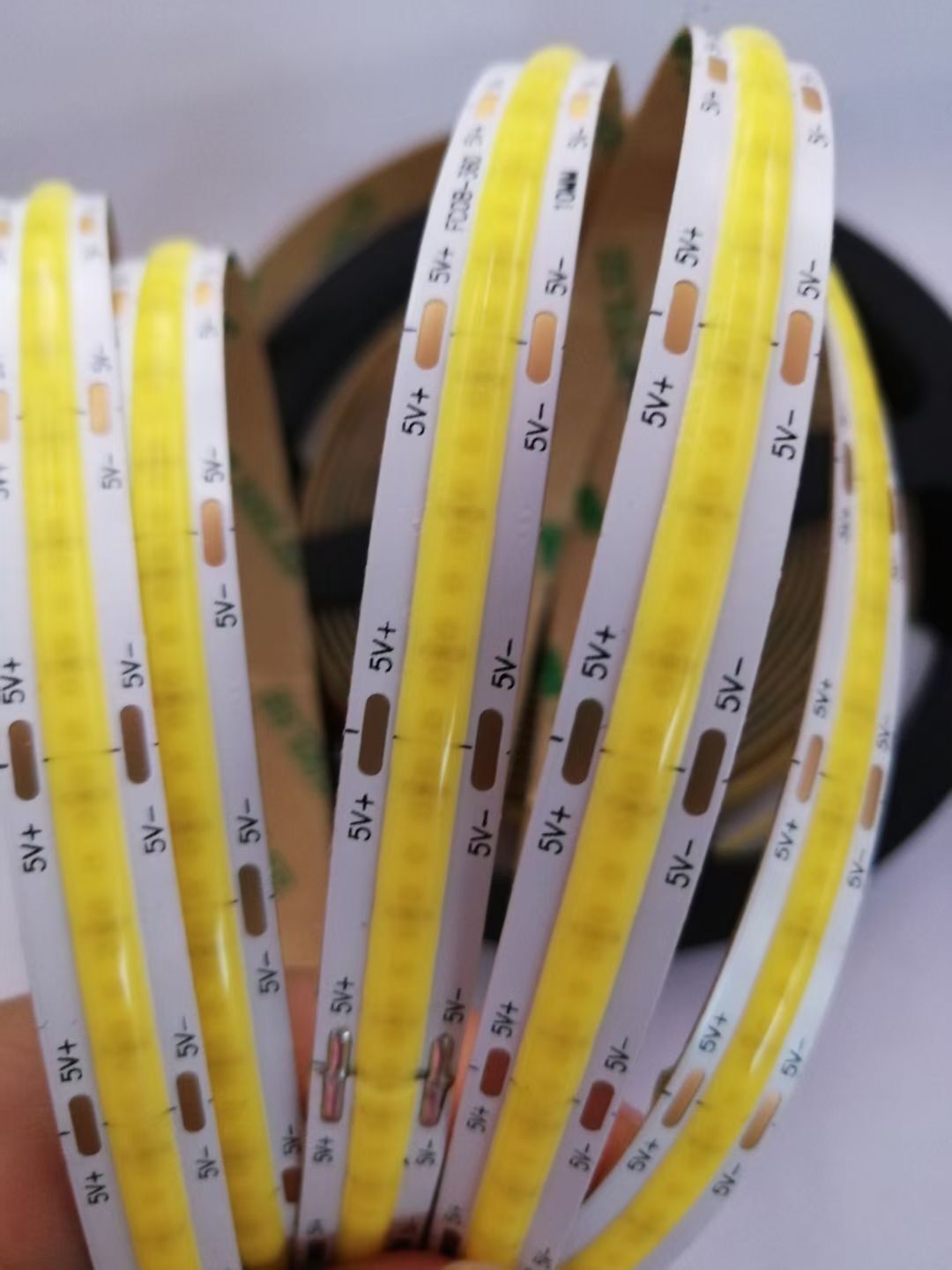

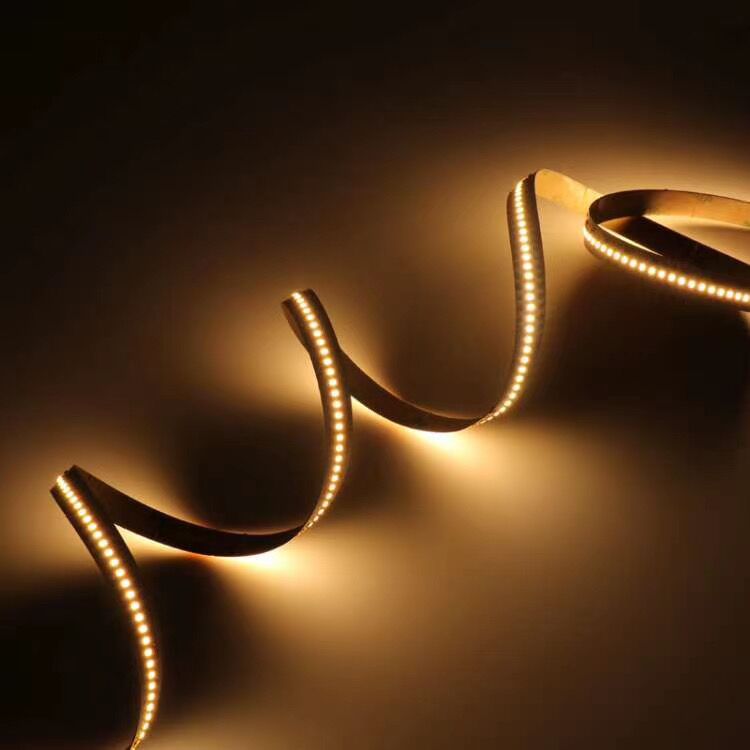

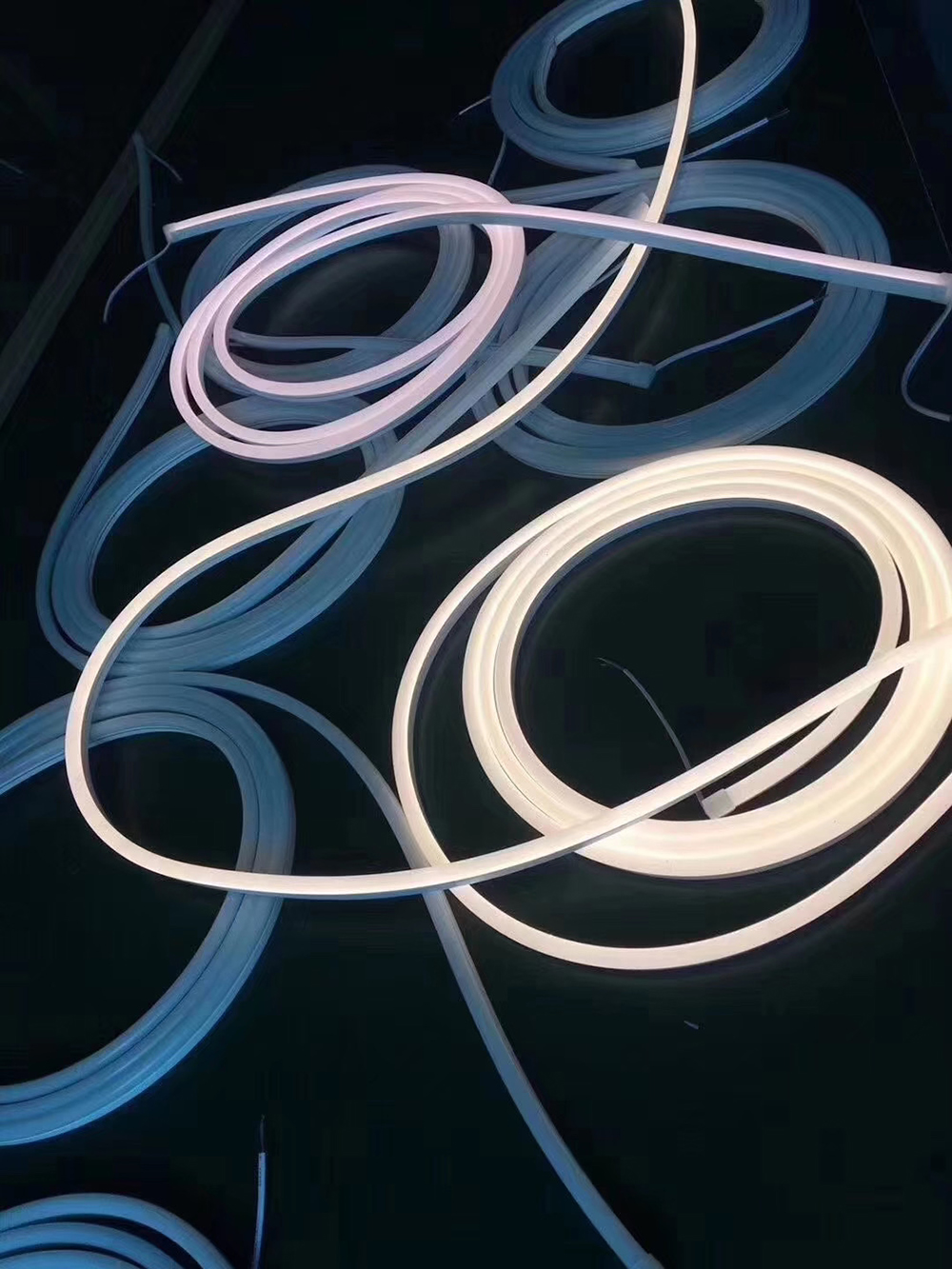

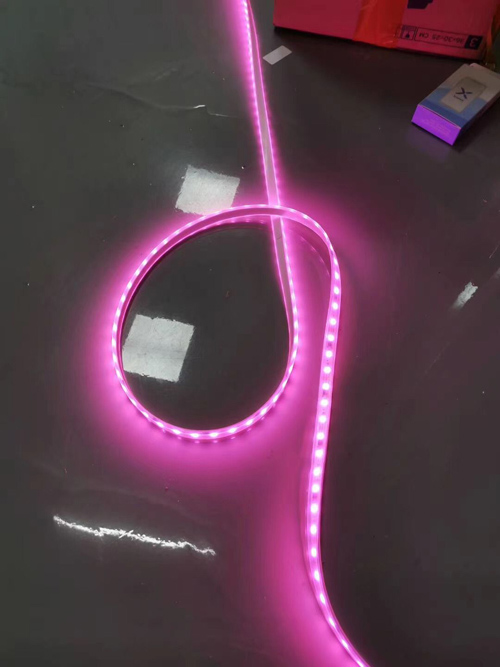

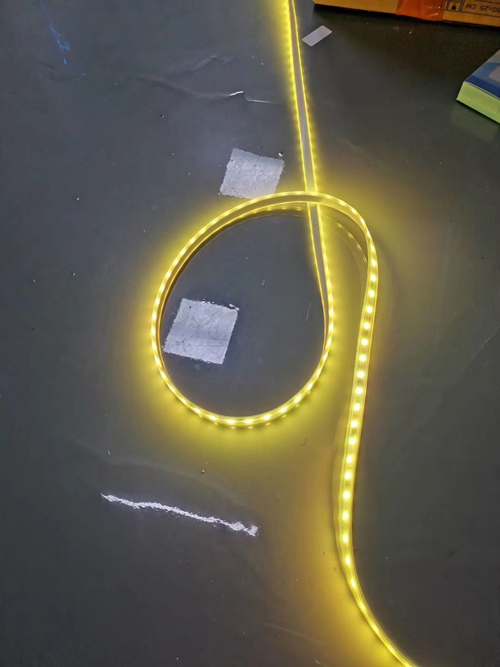

This White LED Strip Light has 3 rows of 2835 LEDs producing 1158 lumens per foot for maximum light output. The high density of 128 LEDs per foot creates a smooth, powerful line of illumination. And with a high CRI (color-rendering index) of up to 94, light from the LEDs will show the true colors of any object or surrounding. Easy to dim for desired brightness with a compatible controller (sold separately). Triple-row strip can be cut in segments of 2" or create a continuous run up to 16.4'. Flexible construction and 3M™ adhesive backing makes it simple to apply to a wide range of applications.

Features:

- 94+ CRI rating ensures vibrant, natural-looking color tones

- 24 VDC input

- Max Run: 16.4ft (5m)

- 21 LEDs/segment

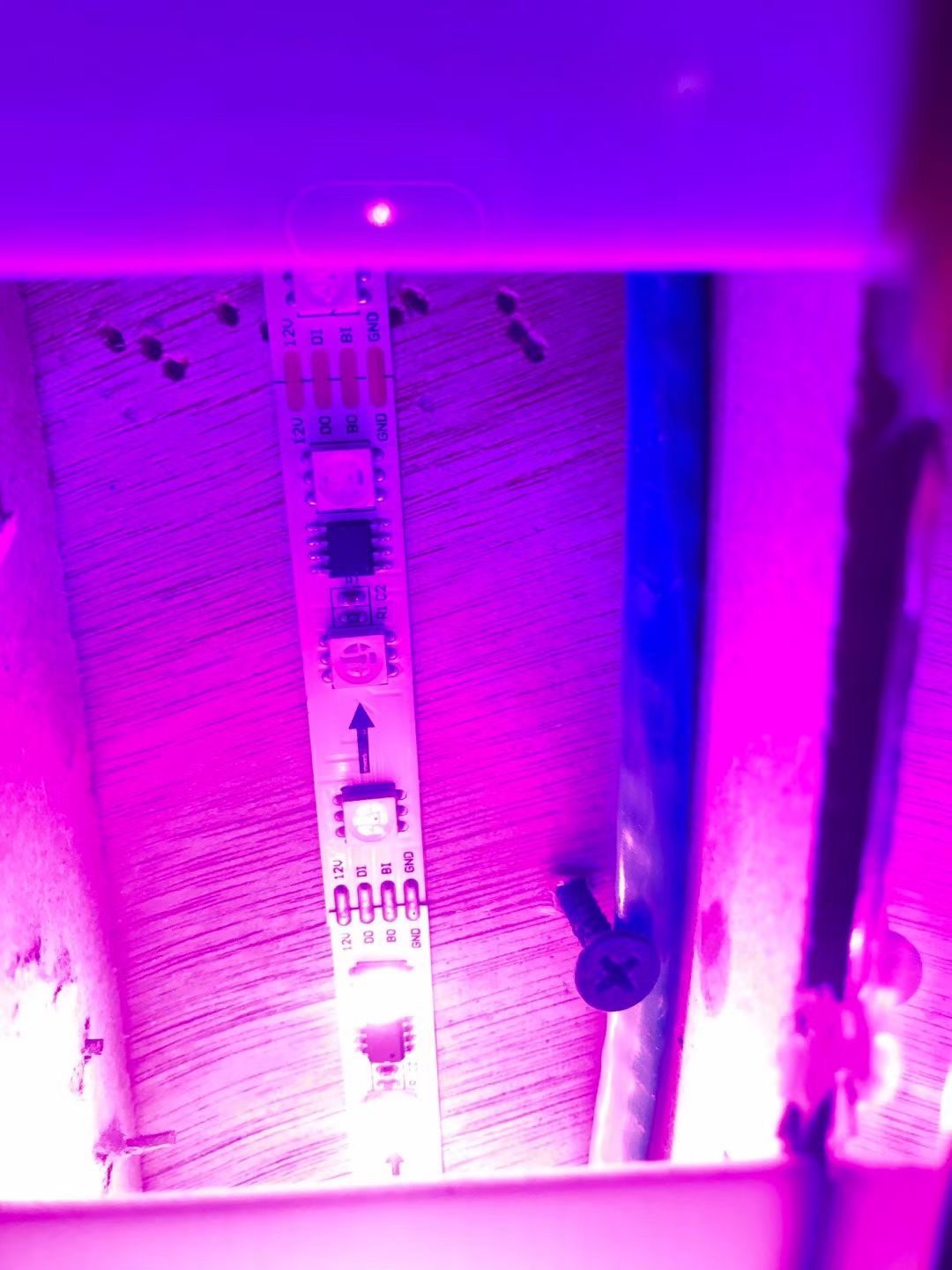

- Segment Length: 1.97in (50mm)

- Density: 128 LEDs/ft

- Strip Width: 25mm (0.98in)

- Dimmable: 0-100%

- IP20 rated for dry conditions

- 36000 hours L70 lifespan

- CE certified

- 5 year warranty

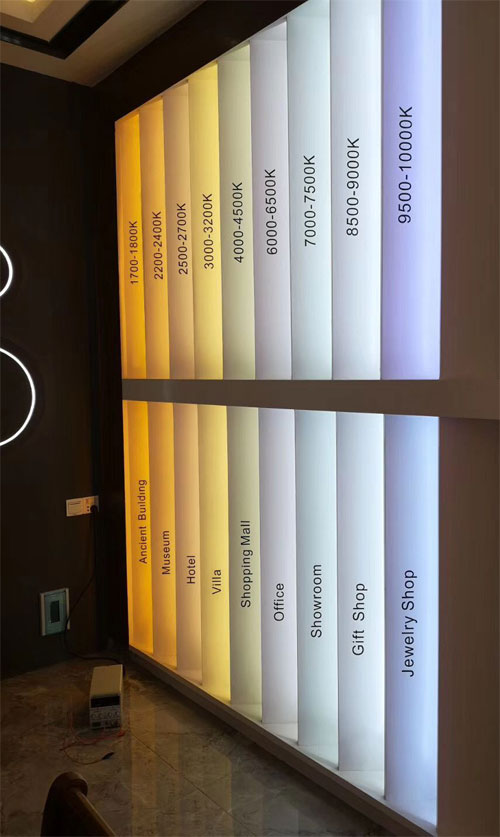

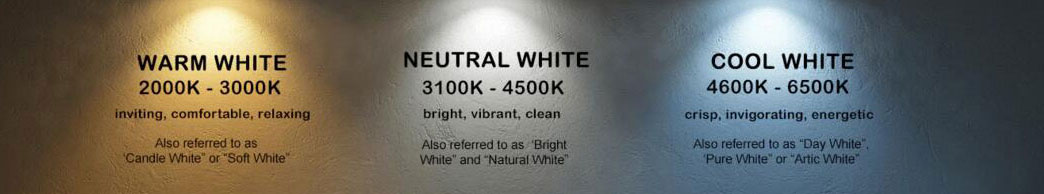

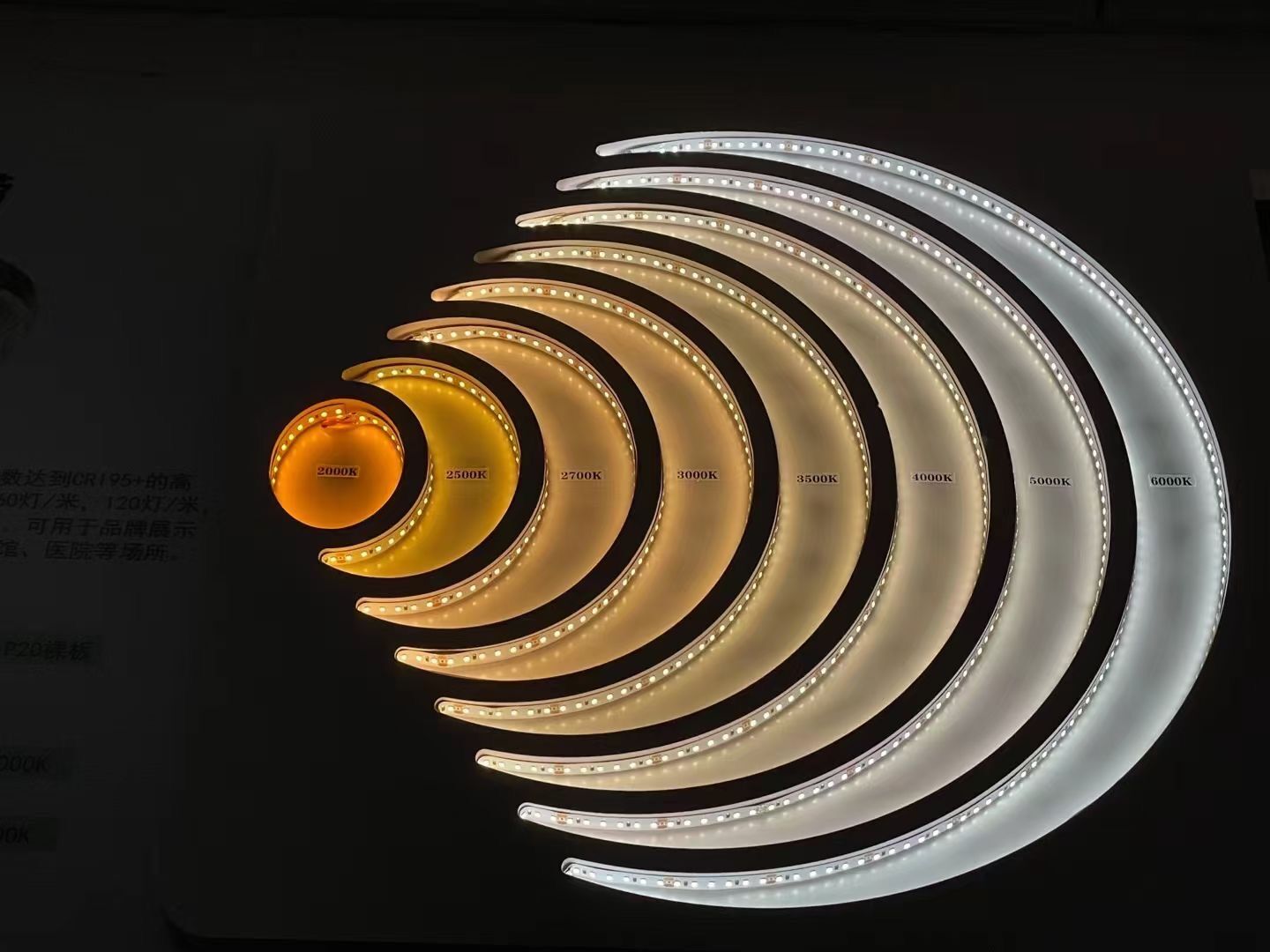

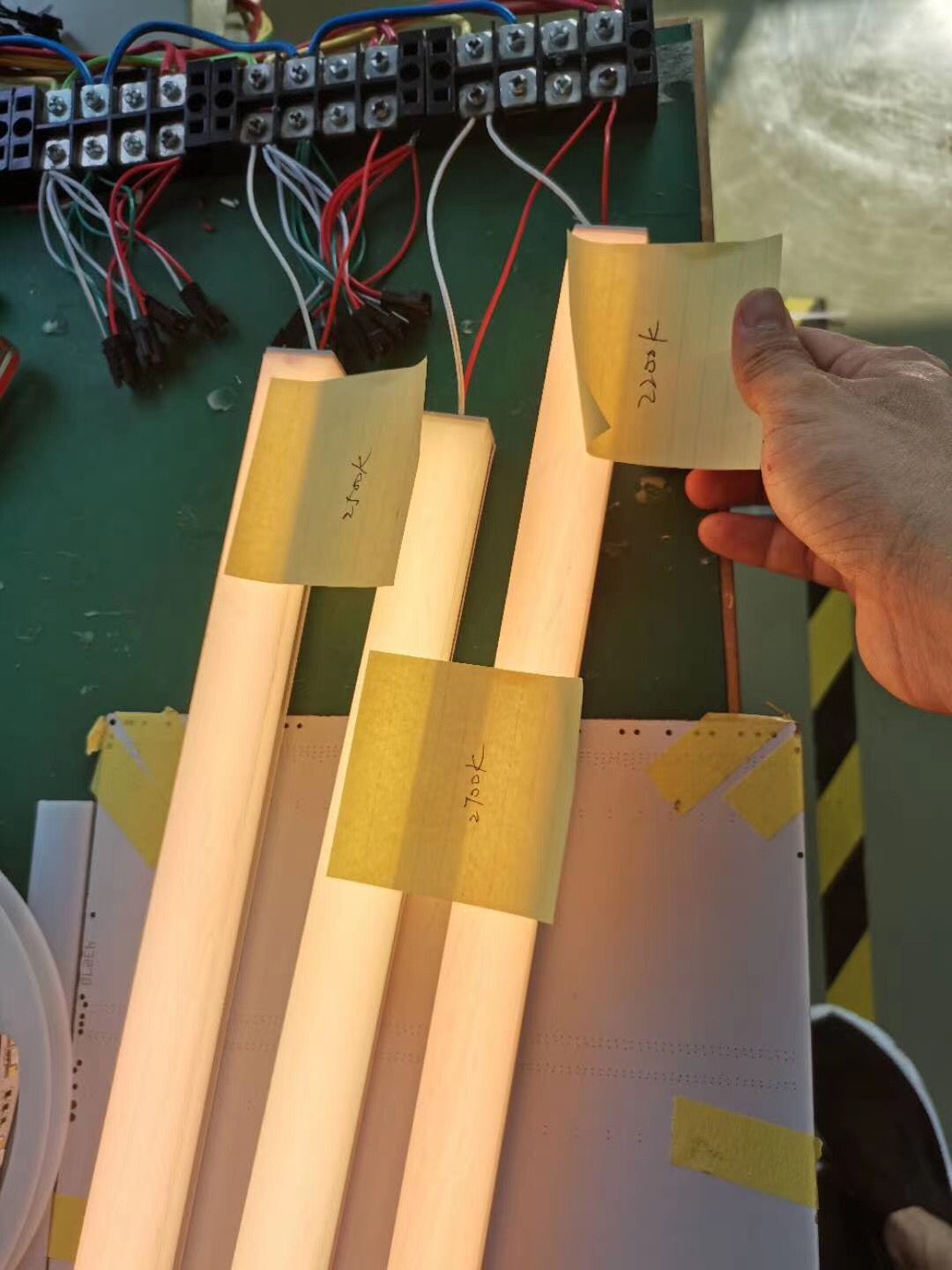

Available Colors CCTs

Warranties & Certifications

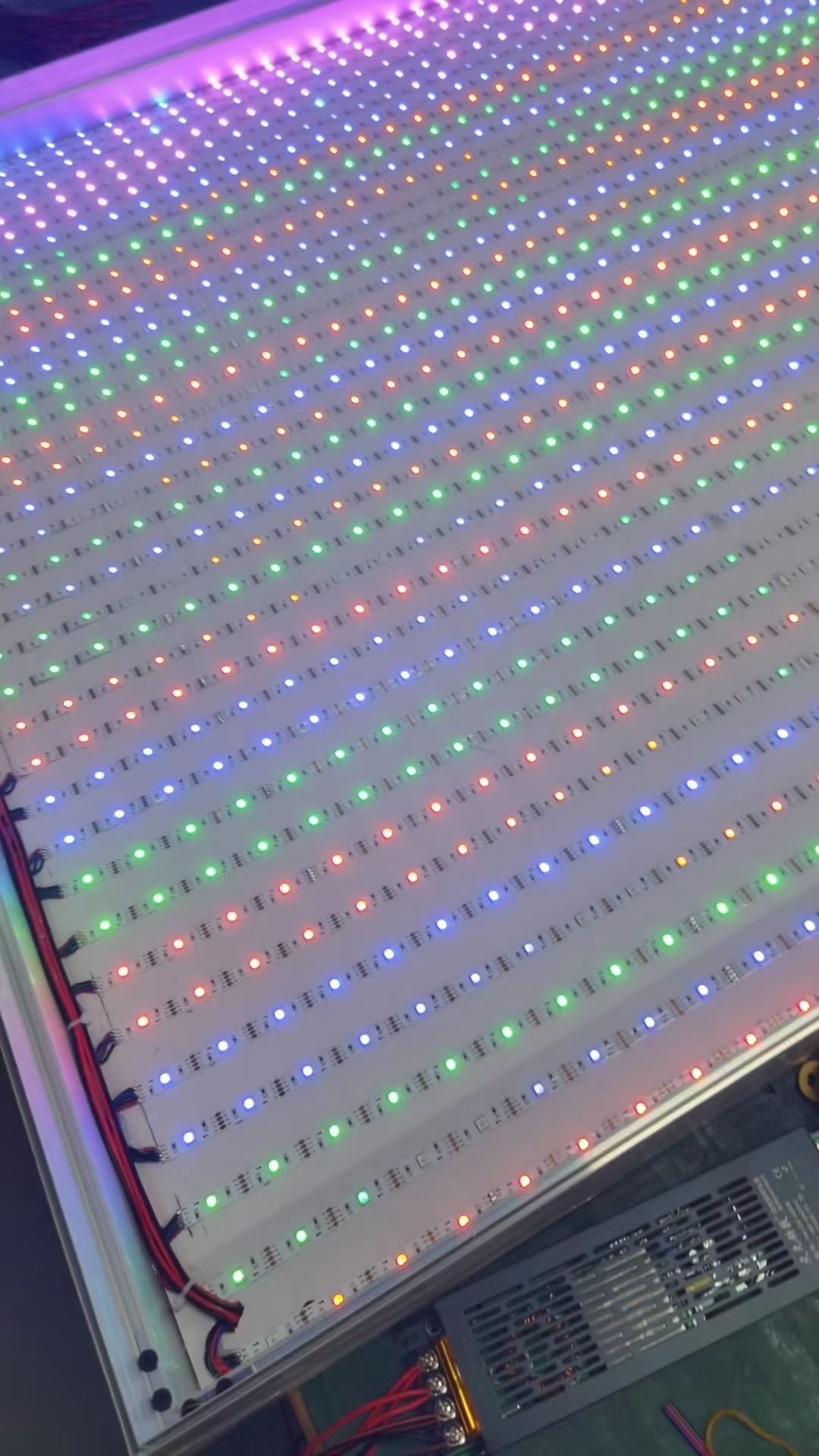

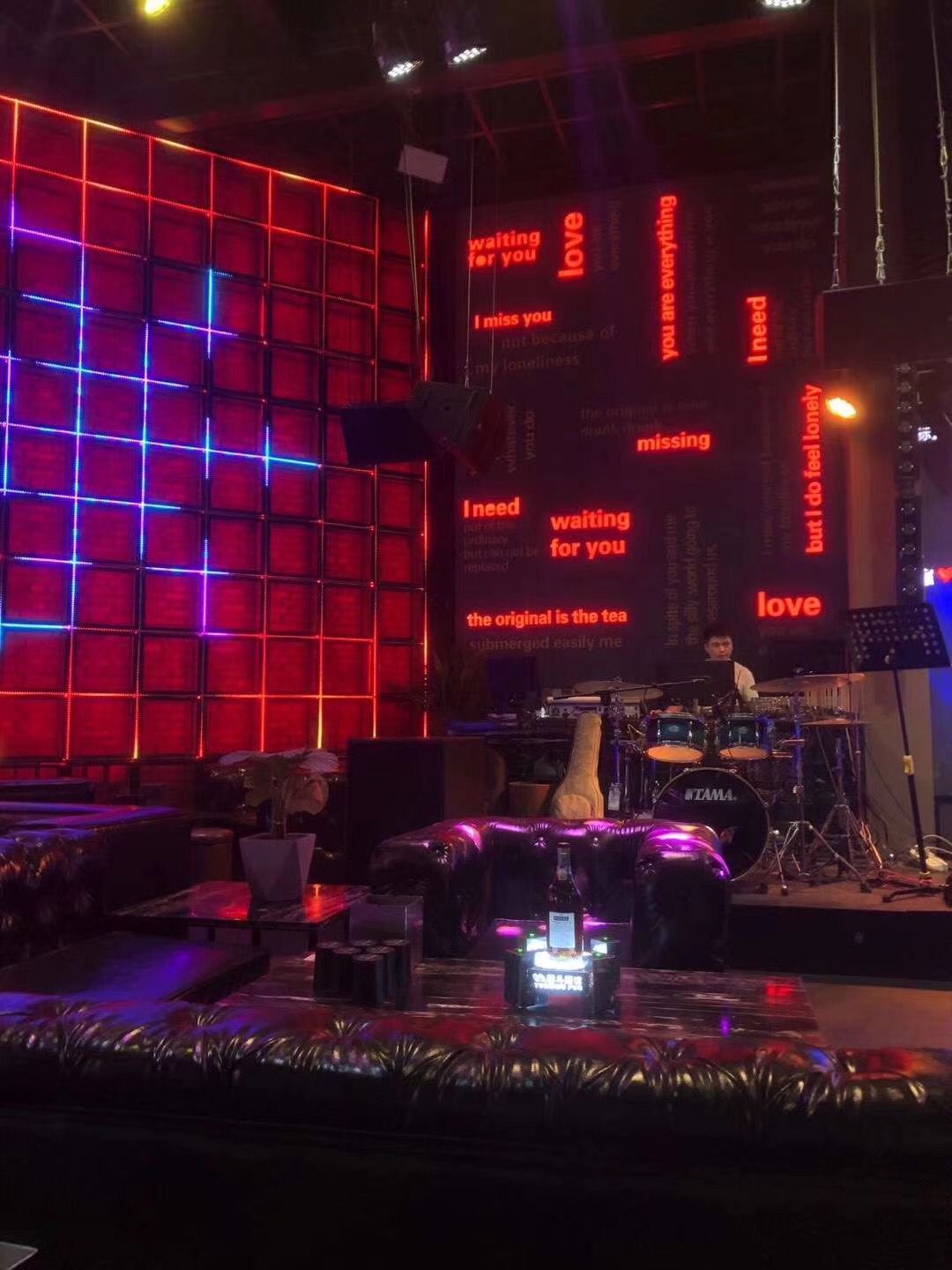

Application & Use

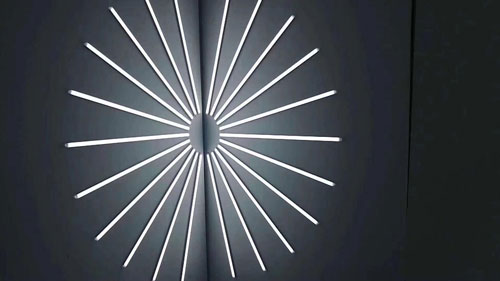

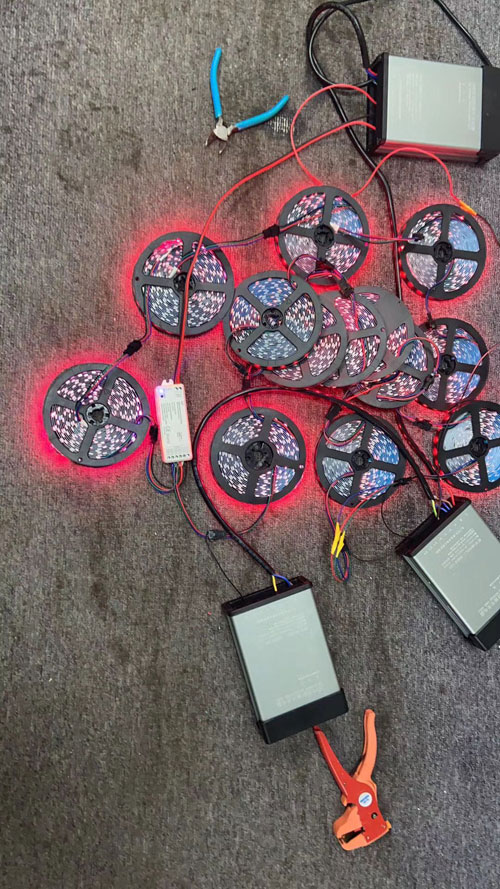

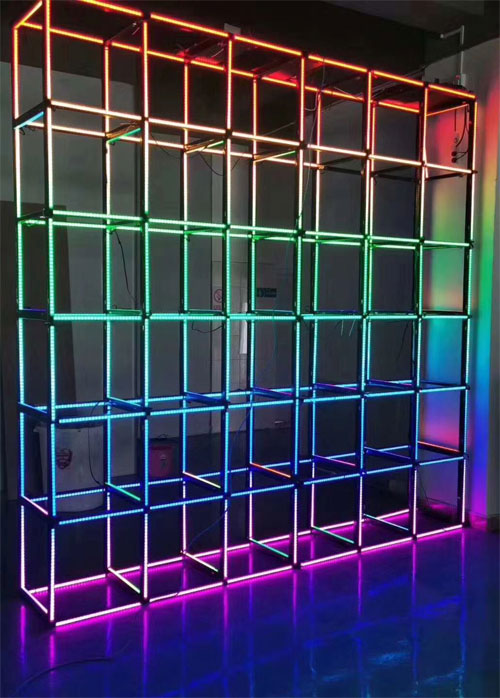

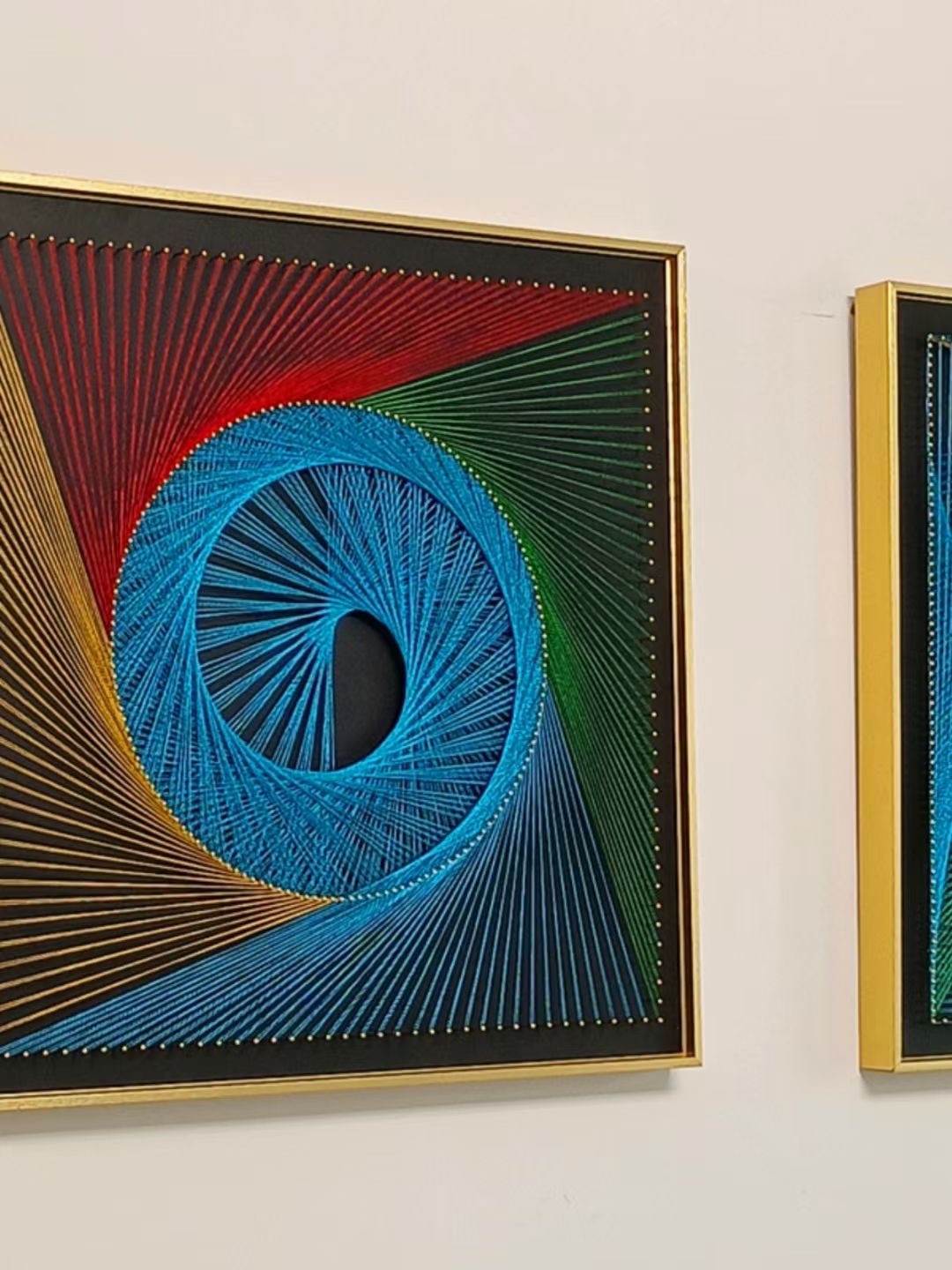

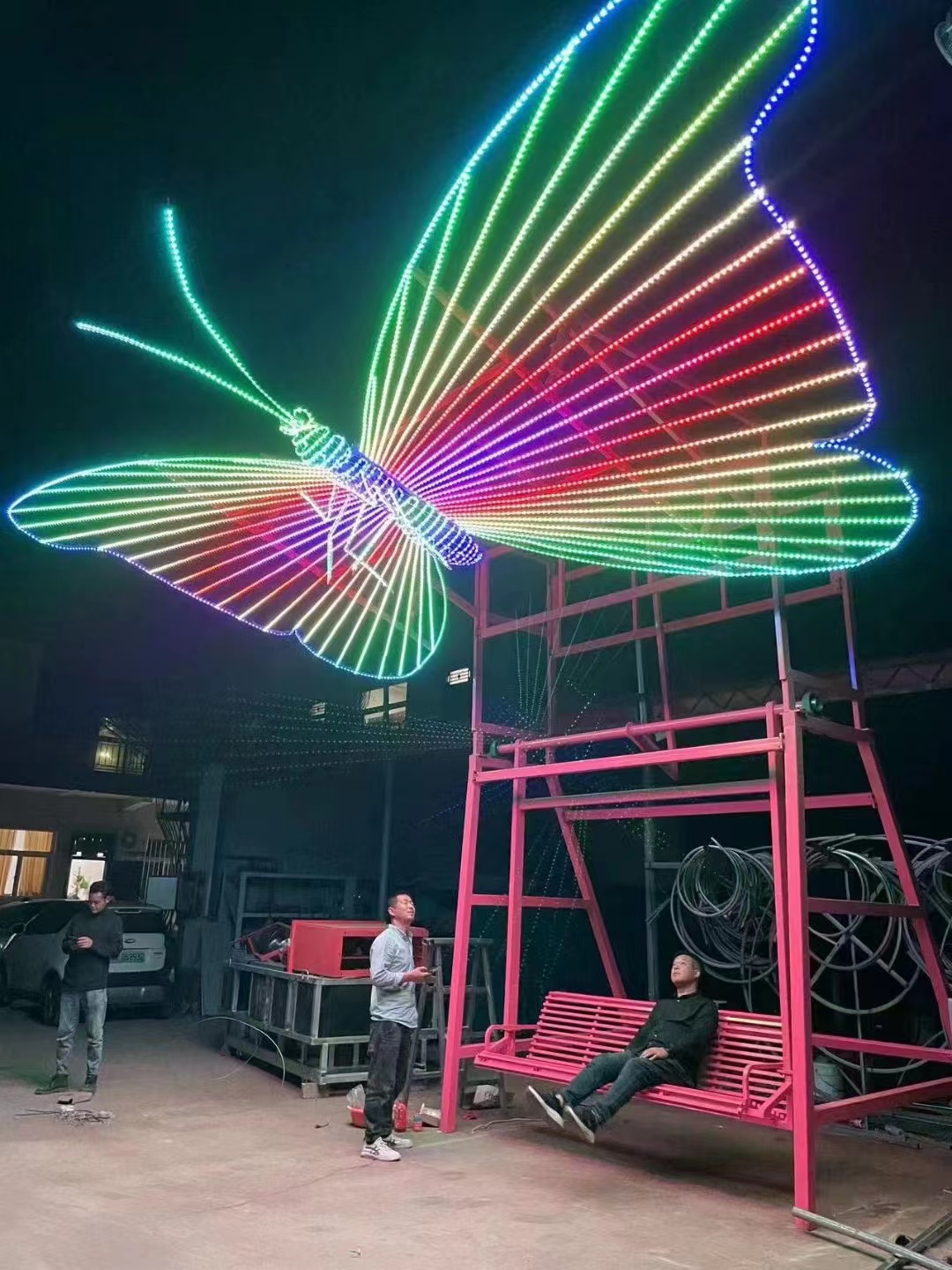

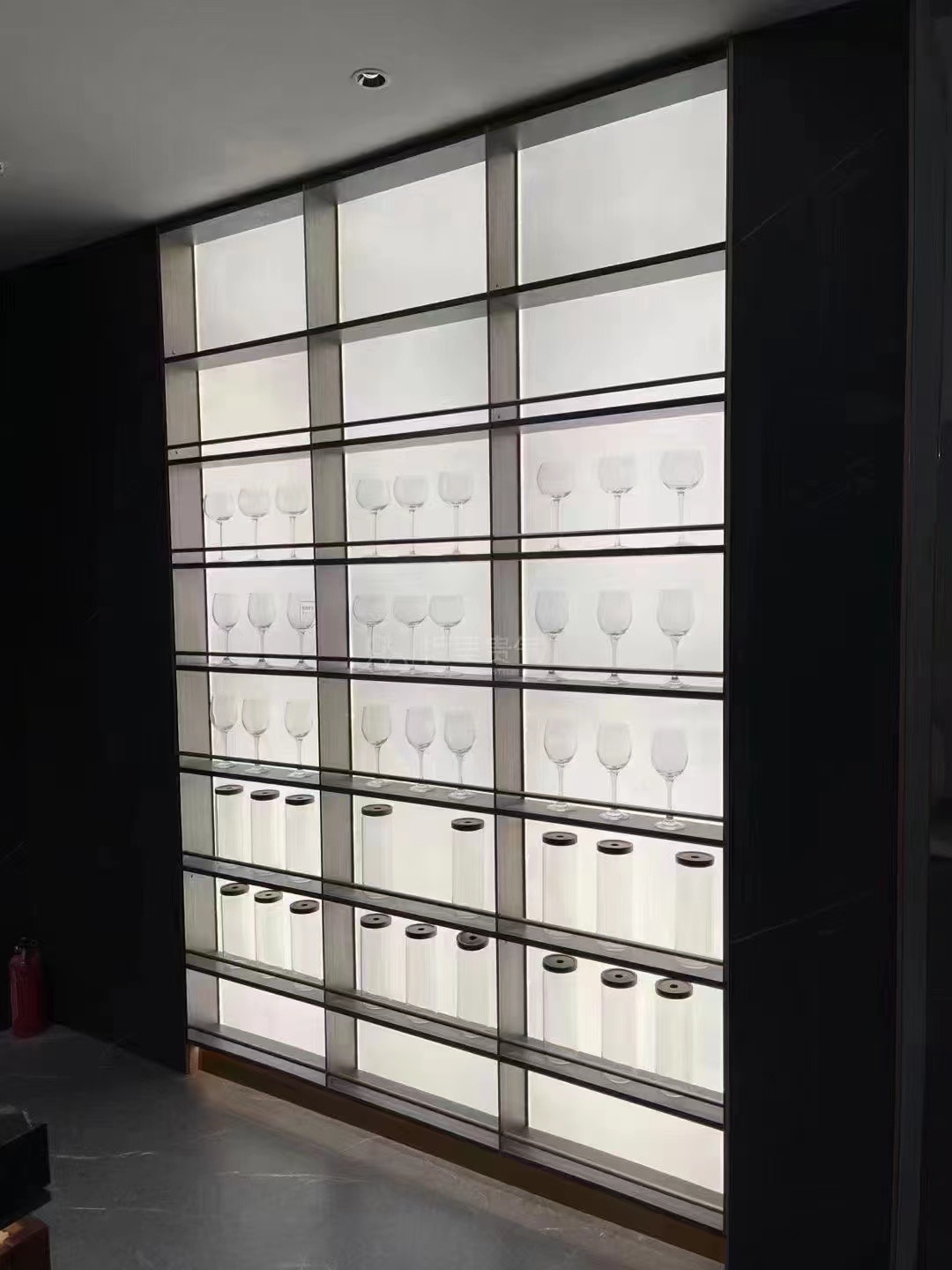

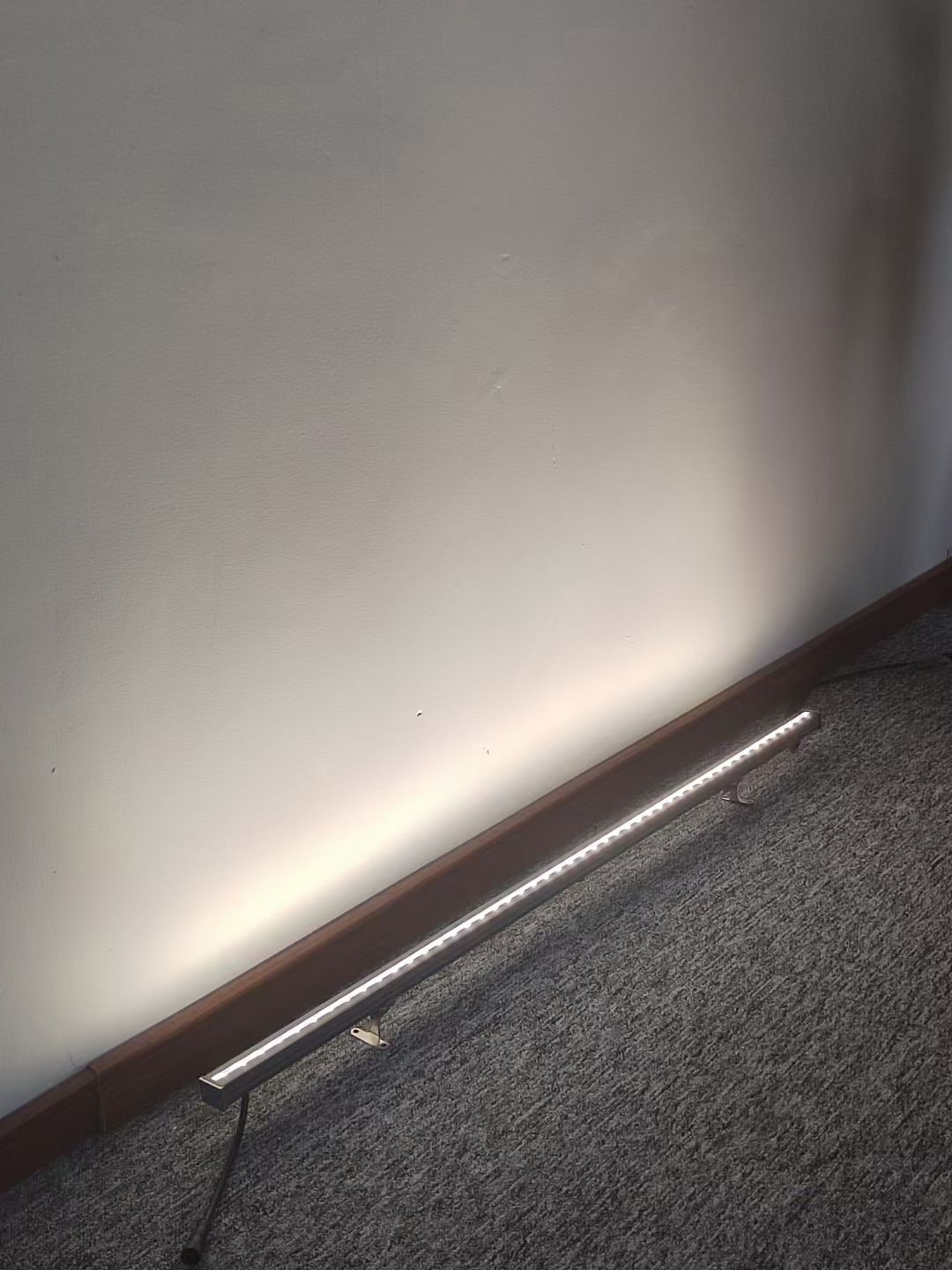

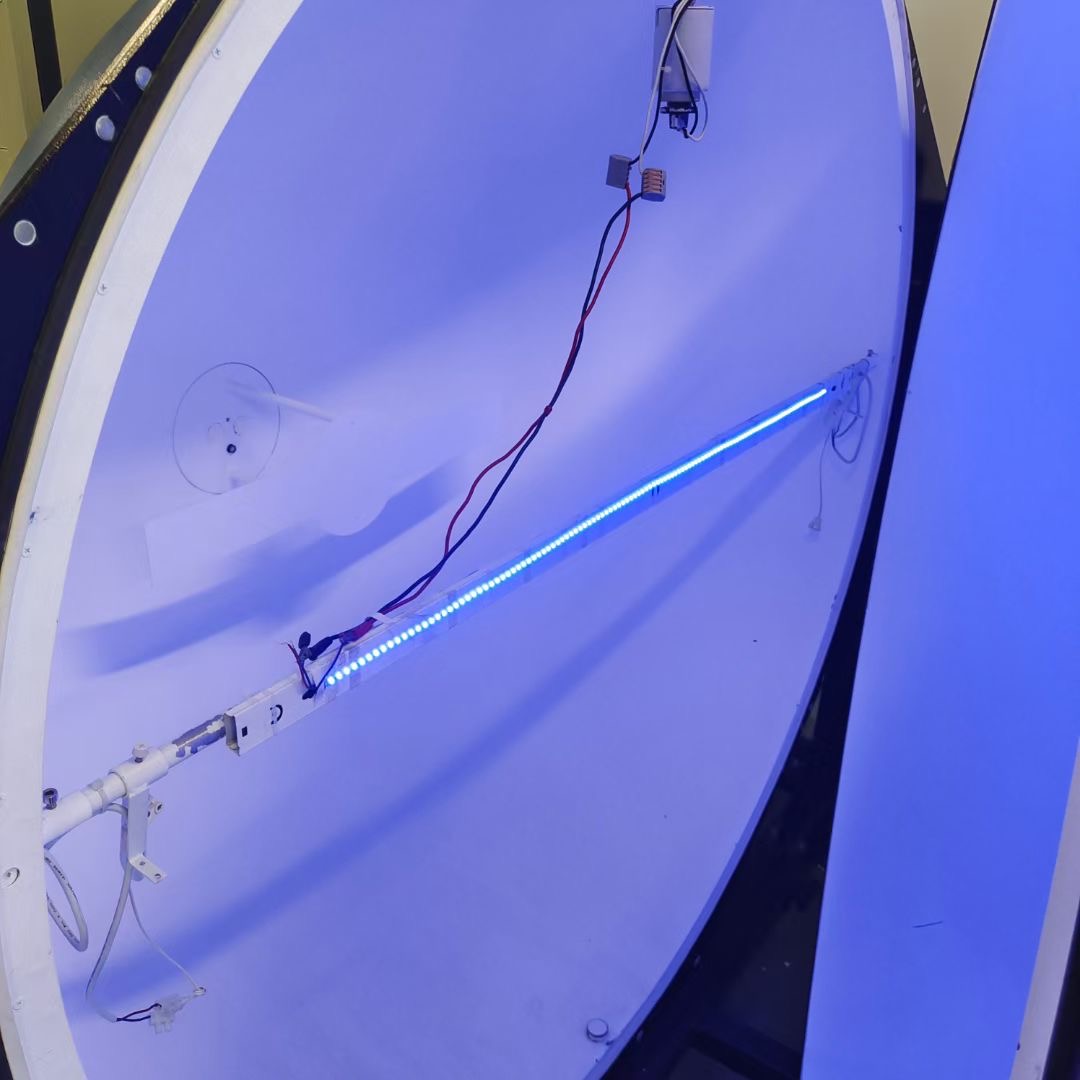

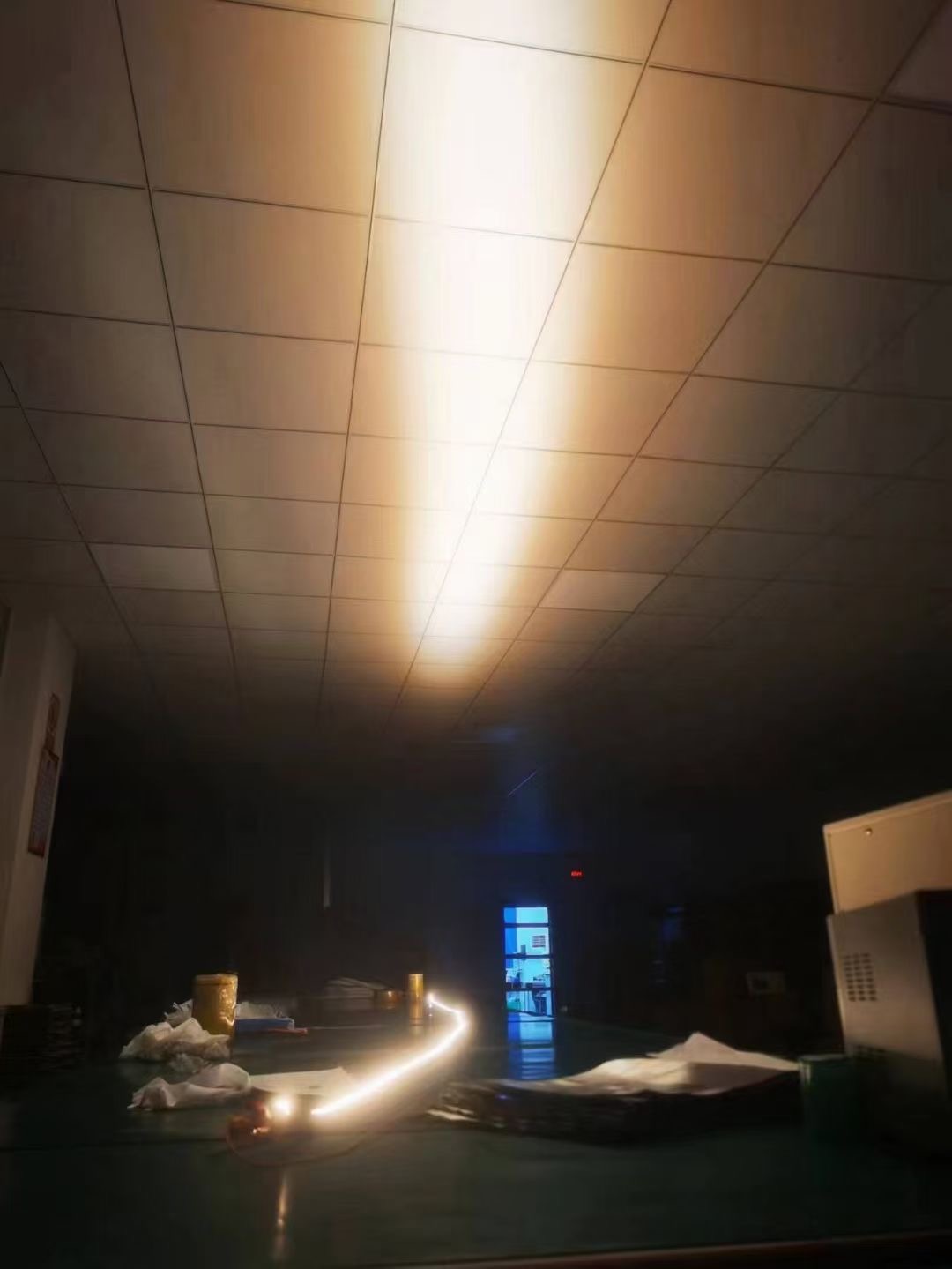

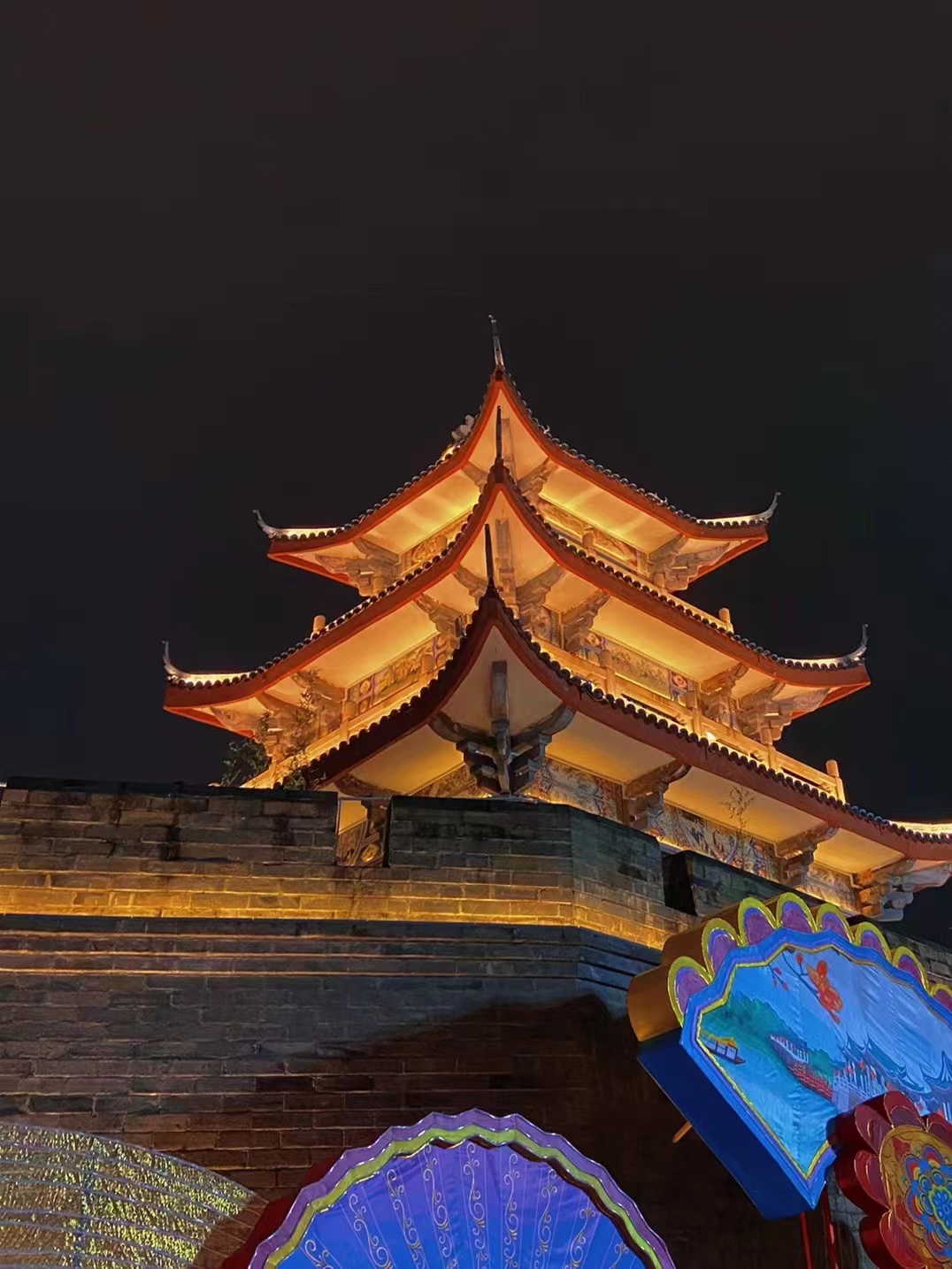

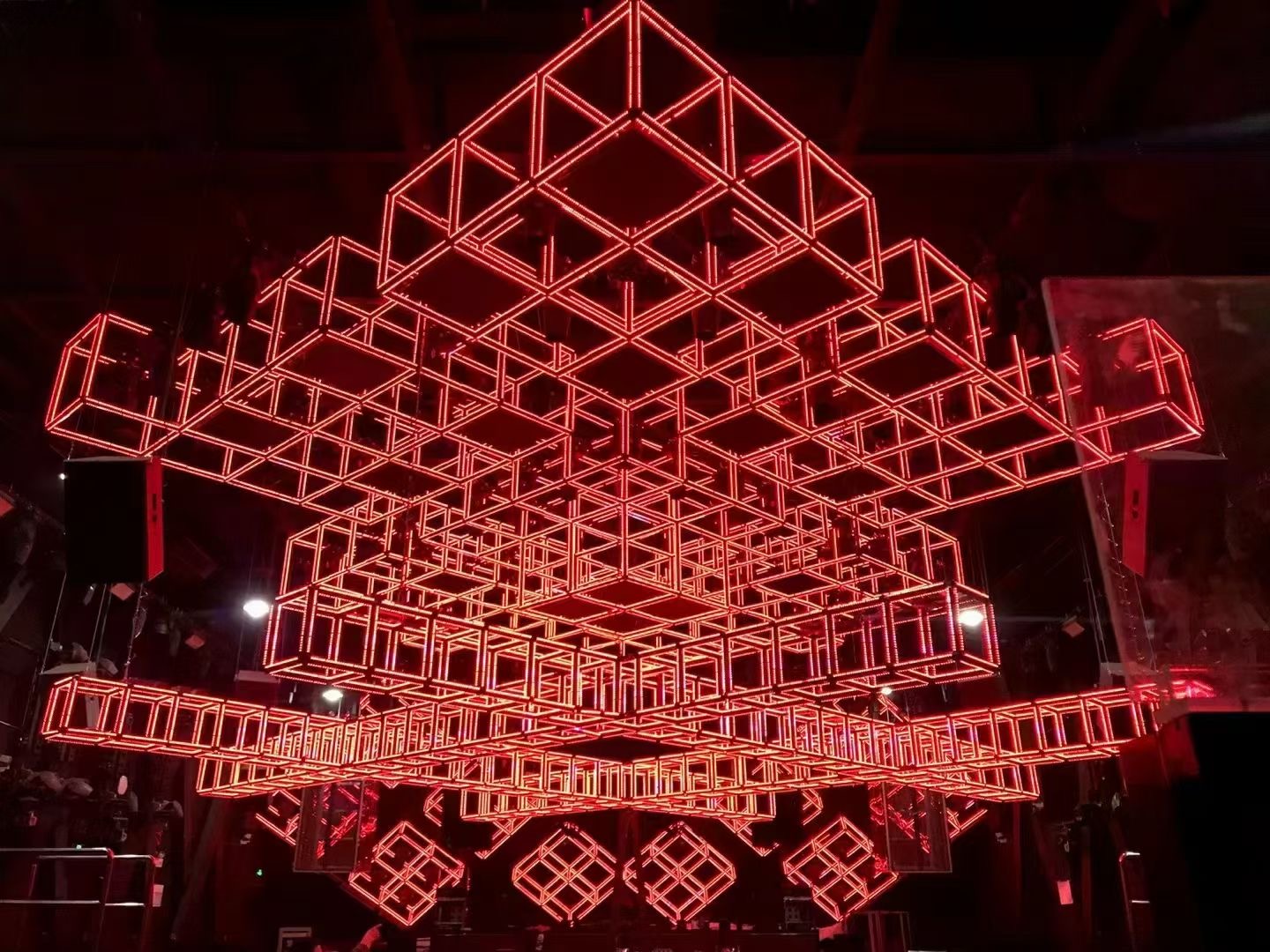

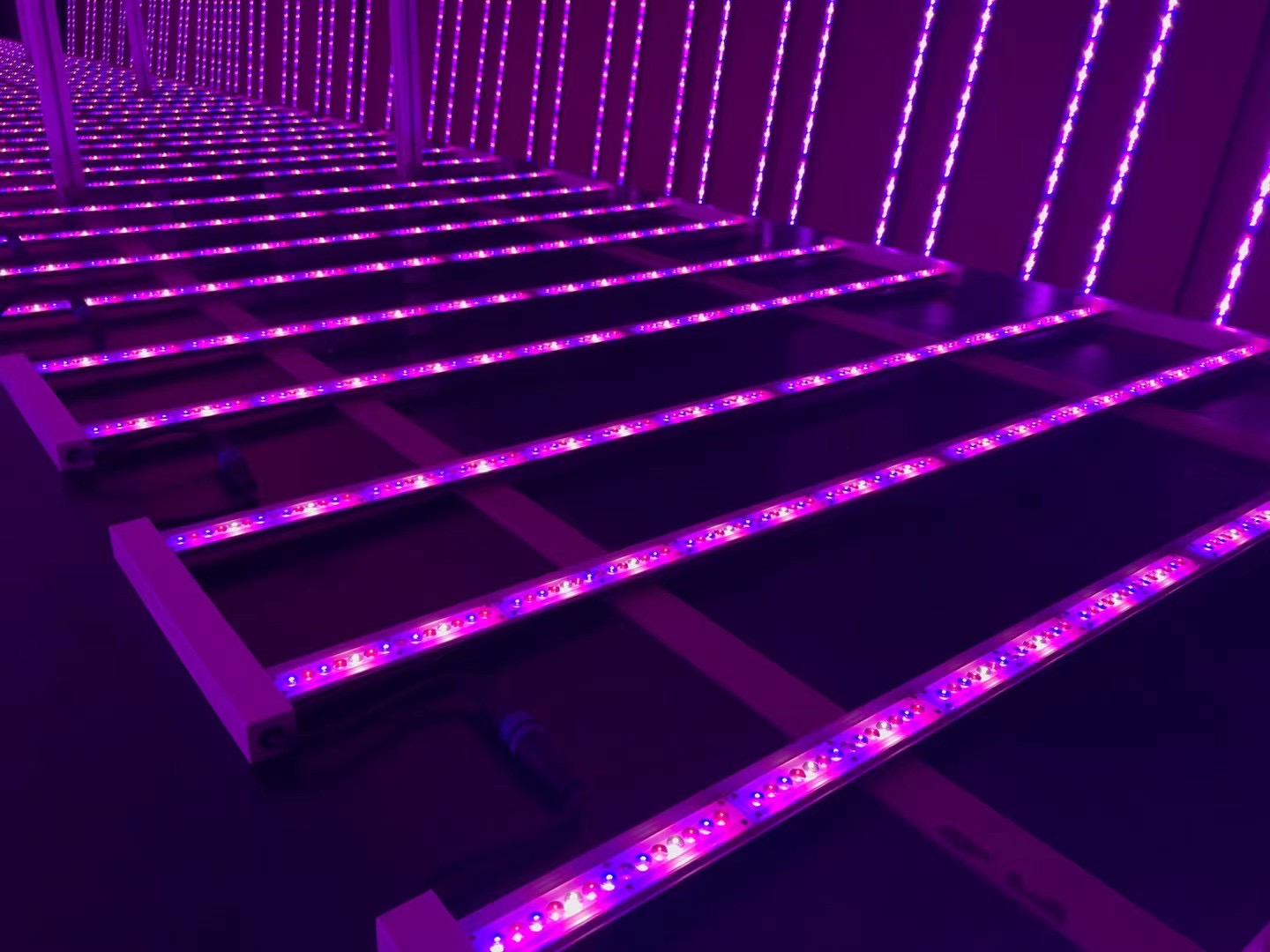

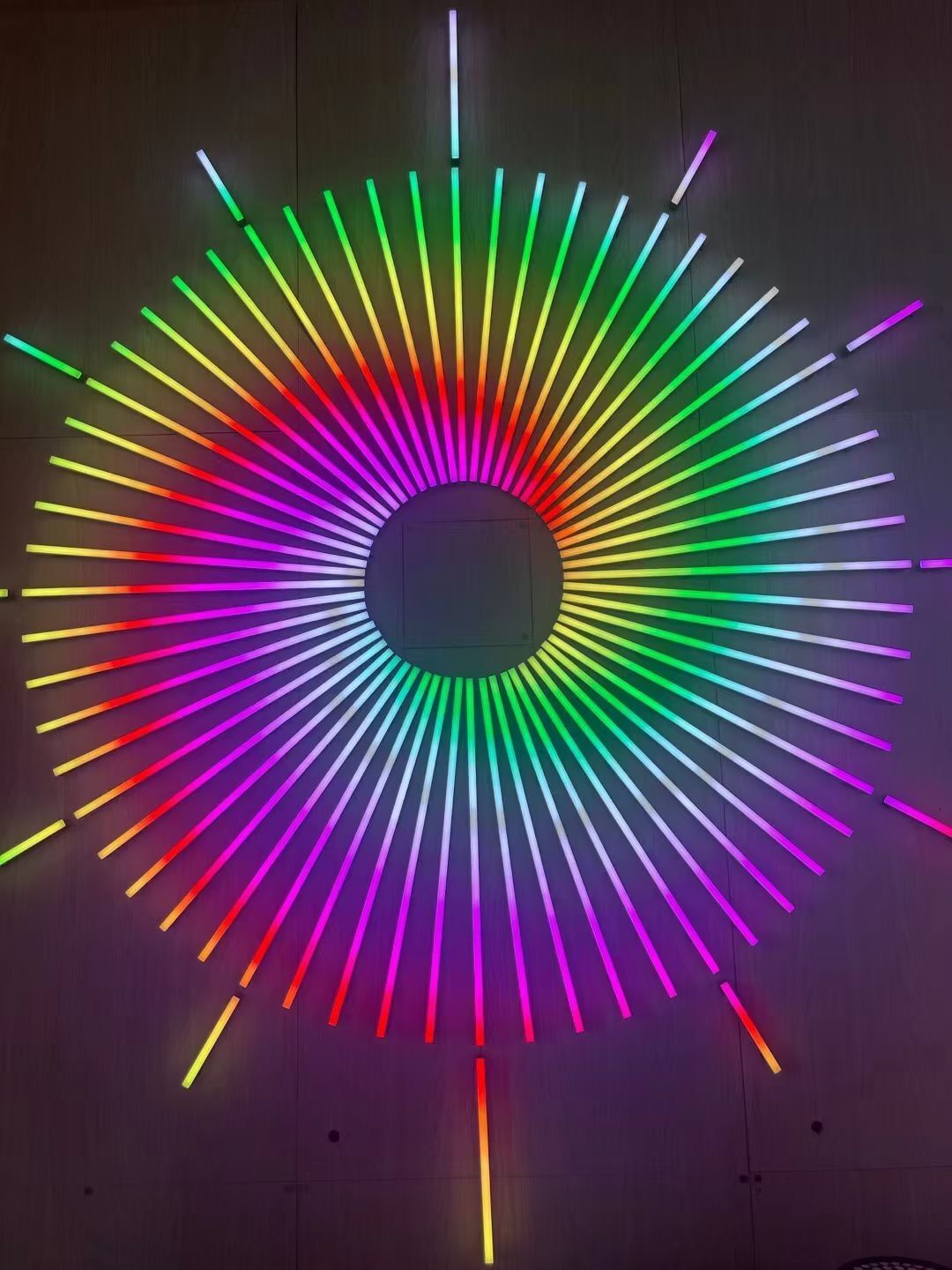

SmartBrightLEDs White Series LED strip lights are installed in a wide variety of applications including:

TV backlighting, Linear lighting, Cove lighting, Display / jewelry case lighting, Bar and restaurant accent lighting, Above cabinet lighting, Under counter lighting, Hotel lobbies, Cove lighting

TECHNICAL DETAILS

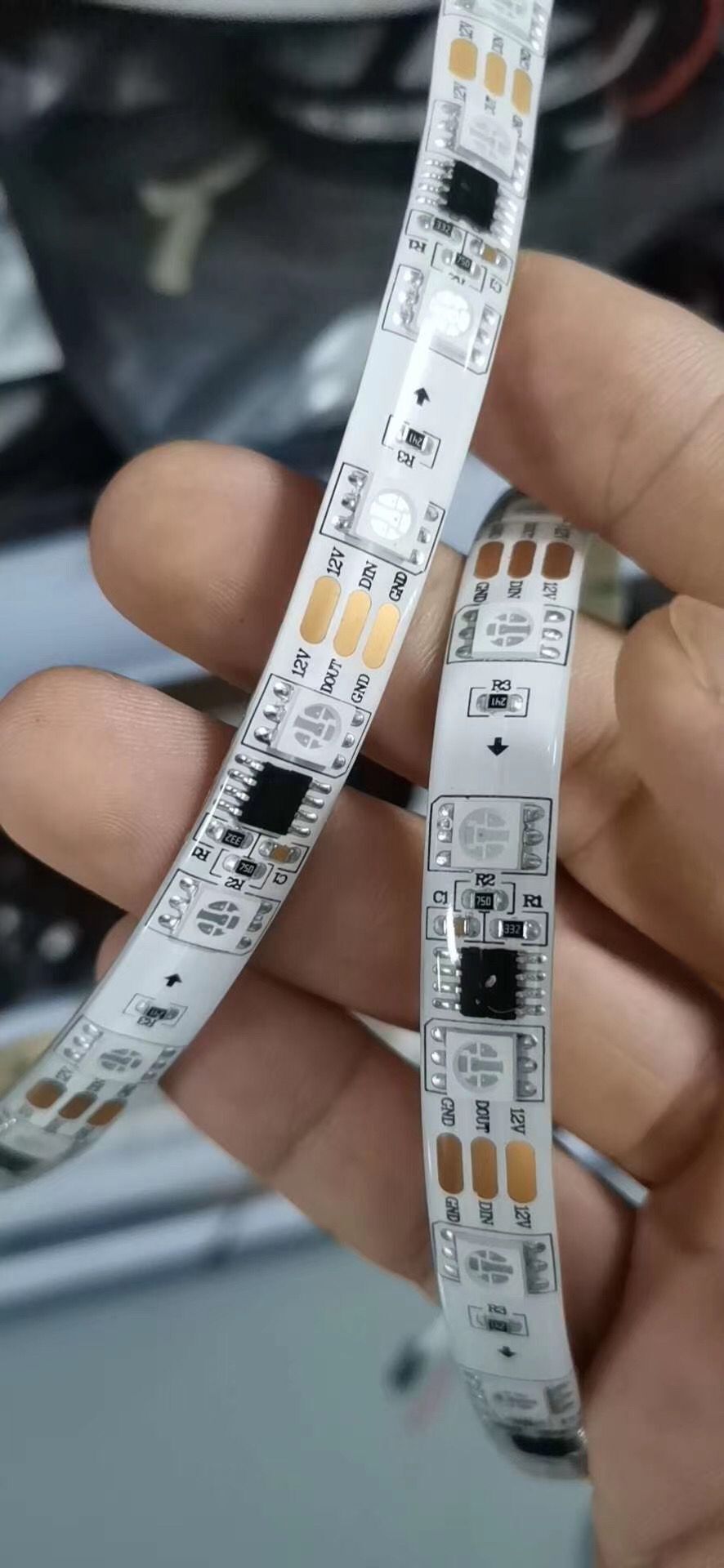

| Voltage | 24V DC |

| LED Beam Angle | 120° |

| Brightness | 1158 lm/ft |

| LED Density | 128 LEDs/ft |

| CRI | 94+ |

| Special Features | High CRI |

| Strip Width | 25mm (0.98in) |

| LED per Segment | 21 |

| Segment Length | 1.97 in. (50 mm) |

| Max Run | Up to 16.4ft (5m) |

| Rated Lifespan | 50,000 hours |

| Length | 16.4ft (5m) reel |

| Dimmable | Yes (requires controller) |

| Wattage per Foot | 11.6 W/ft (38 W/m) |

| Wattage | 190 Watts |

| Protection Rating | Non-Waterproof IP20 |

| Connection Type | Pigtail |

| Current Draw | 7.92 A total (483 mA/ft) |

| Operating Temperature | -20~+45 °C (-4~+113 °F) |

| Standards And Certifications | CE, RoHS Compliant |

**All specifications are subject to change without notice.

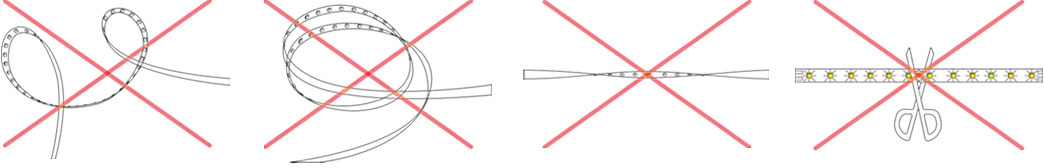

Incorrect Use:

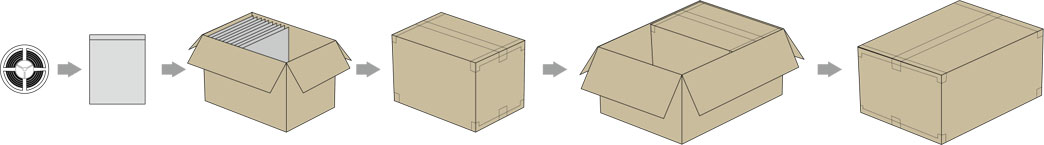

Packaing Diagram

Use of environmental conditions

1). LED strips installation must be operated by professionals.

2). For avoiding LED get vulcanized, LED strip should be installed in the environment where does not has oil and corrosive substances. Such as these substances which contain Sulphur、Bromine、Iodine and Chlorine. Some other chemical elements which will cause Aromatic hydrocarbons releasing(such as: methylbenzene、xylene、methyl acetoacetate Ethyl acetate etc.).The environment in which includes strong acid and strong base.

3). For cutting LED strip operation, it is necessary to use the standard accessories provided by smartbrightLEDs (e.g. DC wire, end-cap, front-cap, adhesive, etc.), and according to the correct cutting and connecting method for the installation.

4). LED strip cannot be installed in some areas where water hazard might be formed, such as the surface of pits and ditches. And similar places in which rain and water may be accumulated easily.

5). Please do not strongly pull、crash the LED strips during installation process. And avoid squeezing and scratching LED strips with sharp objects.

6). During the warranty period, only defective products are acceptable to be replaced by the factory. Factory is not responsible for other expenses because of replacement,such as transportation fee, installation fee, etc.

Cautions Cautions1. In order to guarantee the LED life and the use environment, cannot make any force when the product lighting use to pull the power cables, forbids to collide, in order to avoid damages LED. 2. For better lighting effect of the product, each 5 meters strip must connect the main power source. 3. Must guarantee that each power source (GND) must be connected. 4. Should not be curving in the diameter 60mm following radian, please do not rebate, in order to avoid damage lamp bead or break. 5. Please follow the user manual for installation. 6. Please note the careful operation, in the power source connection's situation, will touch the alternating current supply end possibly to cause your safety. 7. In the actual application, the power source should retain 20% remainders, guaranteed that the sufficiency the voltage lightens LED. 8. Installs as far as possible the product in the appropriate environment. 9. Pays attention to the power cable in the installment process positive and negative extremely, please do not wrong, power source and product voltage to be whether correct, in order to avoid creates the product the damage. |

** If you do not follow the above "Cautions" to operate and result in damaging the product, the factory will not accept maintenance and return.

Related Items

36V White LED Strip Light - High CRI - HighLight Series Tape Light - IP67 - 5m / 30m

3528 White LED Strip Light/Tape Light - 12V/24V - IP20 - 230 Lumens/ft

48V White LED Strip Light - High CRI - HighLight Series Tape Light - IP67 - 5m / 40m

5050 White LED Strip Light/Tape Light - 12V/24V - IP20 - 360 Lumens/ft

3528 Outdoor White LED Strip Light - Dual Row LED Tape Light - 12V/24V - Weatherproof IP65 - 475 lm/ft

5m Dim to Warm (3000K dims to 1800K) LED Strip Light/Tape Lighting - High CRI - 24V - IP20

48V White LED Strip Light - High CRI - HighLight Series Tape Light - IP20 - 5m / 40m

36V White LED Strip Light - High CRI - HighLight Series Tape Light - IP20 - 5m / 30m

Product Review

United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  United States

United States  Canada

Canada  Canada

Canada  United Kingdom

United Kingdom  United States

United States  Canada

Canada  United States

United States  United States

United States  United Kingdom

United Kingdom  Canada

Canada  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  Canada

Canada  United States

United States  Canada

Canada  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  Canada

Canada  United States

United States  United States

United States  Canada

Canada  United States

United States  Canada

Canada  United States

United States  Canada

Canada  United Kingdom

United Kingdom  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United Kingdom

United Kingdom  Canada

Canada  United States

United States  United States

United States  United States

United States  United States

United States  United Kingdom

United Kingdom  Canada

Canada  United States

United States  Canada

Canada  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  Canada

Canada  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  Canada

Canada  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  Canada

Canada  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  Canada

Canada  United States

United States  United States

United States  Canada

Canada  United States

United States  Canada

Canada  United States

United States  United States

United States  Canada

Canada  United States

United States  United States

United States  Canada

Canada  United States

United States  United States

United States  Canada

Canada  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  Canada

Canada  United Kingdom

United Kingdom  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  Canada

Canada  United Kingdom

United Kingdom  United States

United States  Canada

Canada  United States

United States  United States

United States  Canada

Canada  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  United Kingdom

United Kingdom  Canada

Canada  United States

United States  Canada

Canada  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  Canada

Canada  United Kingdom

United Kingdom  United States

United States  United States

United States  Canada

Canada  Canada

Canada  United Kingdom

United Kingdom  United States

United States  United States

United States  United States

United States  Canada

Canada  Canada

Canada  United States

United States  United Kingdom

United Kingdom  United Kingdom

United Kingdom  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  United States

United States  United Kingdom

United Kingdom  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States  United States

United States

Mi-Light & MiBoxer

Mi-Light & MiBoxer Sunricher

Sunricher Skydance

Skydance

LED Strip Light_08_09_2020.jpg)

UltraBright™ Architectural Series LED Strip Light_08_09_2020.jpg)

UltraBright Architectural Series LED Strip Light-CRI 83-07_07_2020.jpg)